Weld Symbols

Contained on this page are examples of weld symbols on different types of fabrication drawings. These drawings range from panels, pipes, custom parts & site instructions. Weld symbols are a necessary part of creating fabrication drawings, as it explains the size & type of weld we require our fabricators to create.

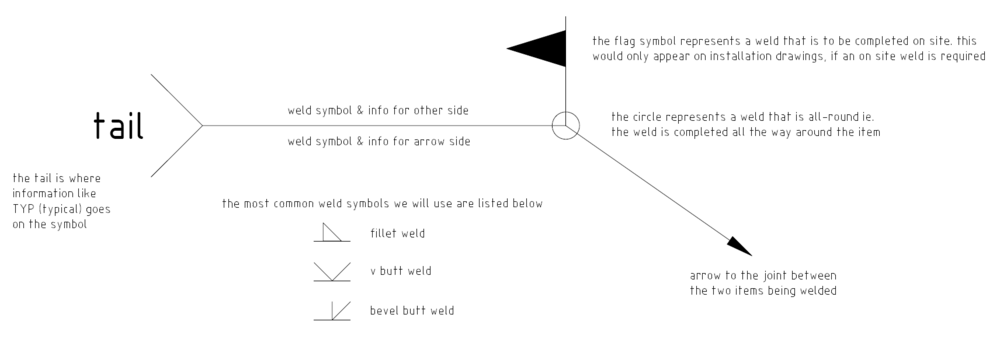

Understanding a Weld Symbol

The weld symbol is an easy representation of the type of weld, its size, and other processing and finishing information. Below is an example weld symbol, showing the structure of the symbol & what each part represents.

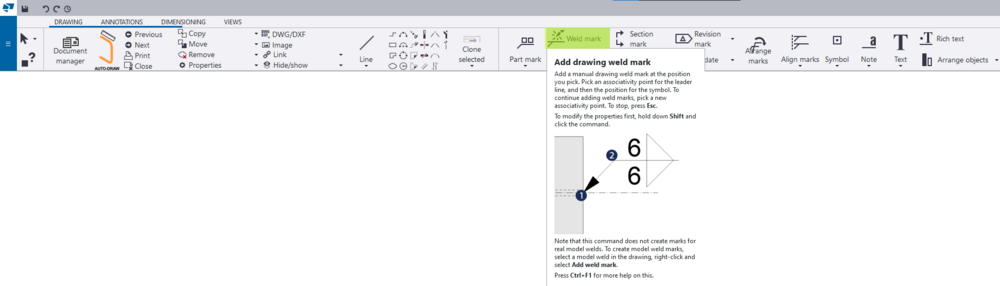

Tekla Toolbar

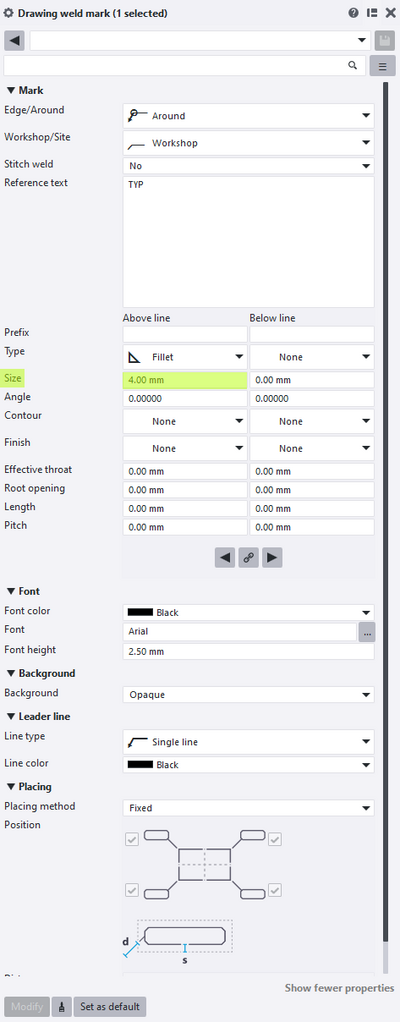

Below images show the process of adding in weld marks to drawings within Tekla. Included are the properties that can be adjusted to create the weld you require, standard weld marks can be selected & used from the drop down menu at the top of the weld mark properties table.

Location of 'Weld mark' in Tekla Toolbar

Select the tool, then click on the area of the drawing you want the weld mark to point to.

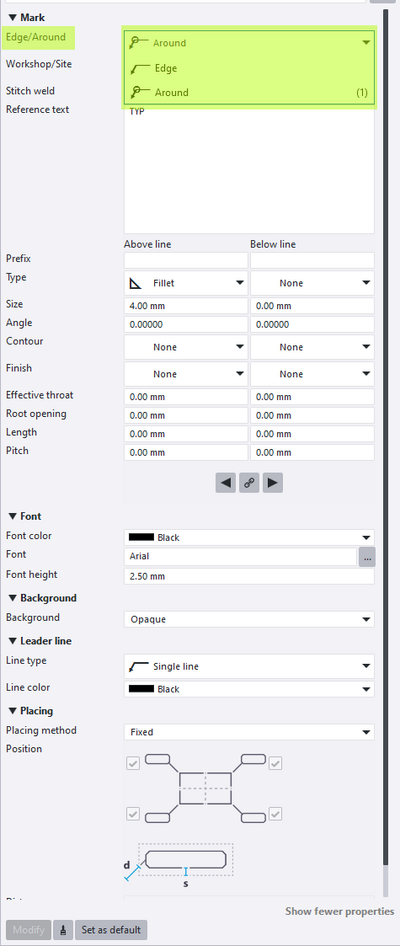

Edge/Around

This option represents a weld that is either along an edge or all around the item (eg. a weld all the way around a rod).

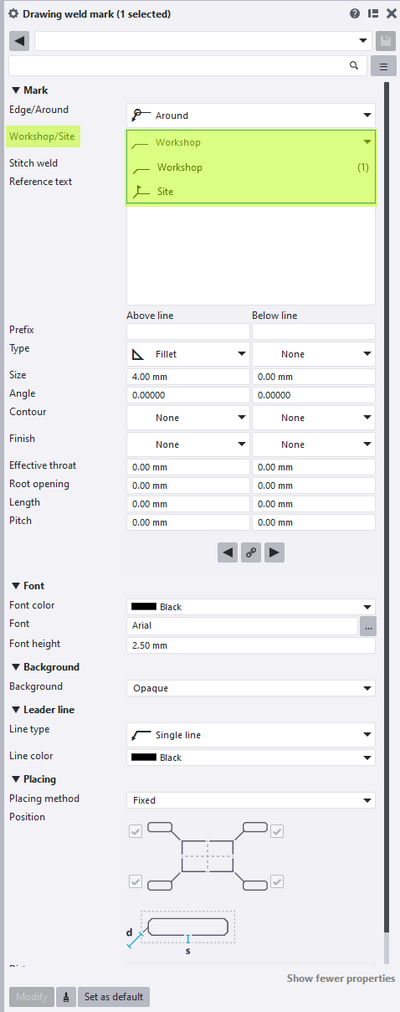

Workshop/Site

This option selects whether the weld is to be completed in the workshop or on site. A majority of our welds will always be workshop, on site welds would only be located on our Installation Drawings (ID), if required.

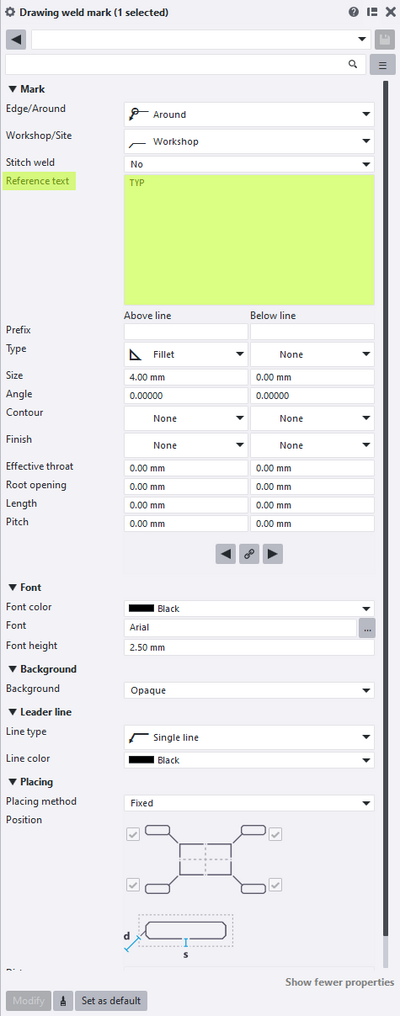

Reference Text

A text field, this adds a tail to the weld symbol when text is entered. Information like process or specification can be entered here (eg. TYP, CFW).

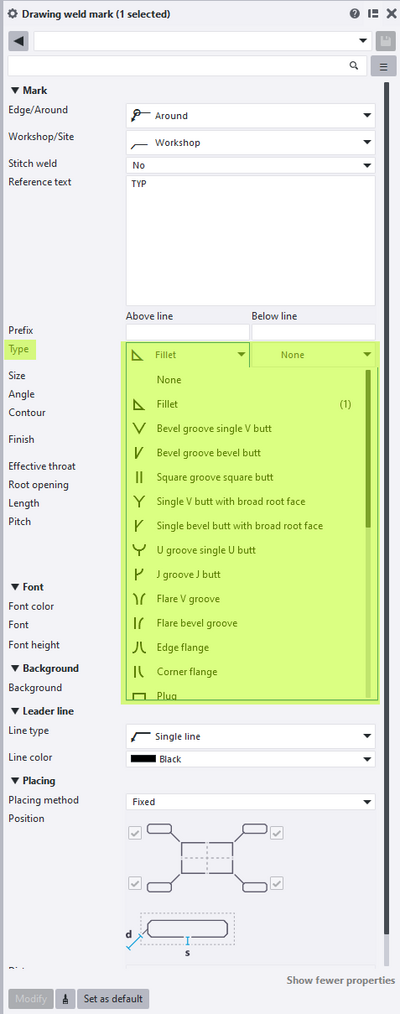

Type

This dropdown contains all of the different weld symbols that can be selected.

Size

A text field, this is the actual size of the weld that will be completed.

Panels

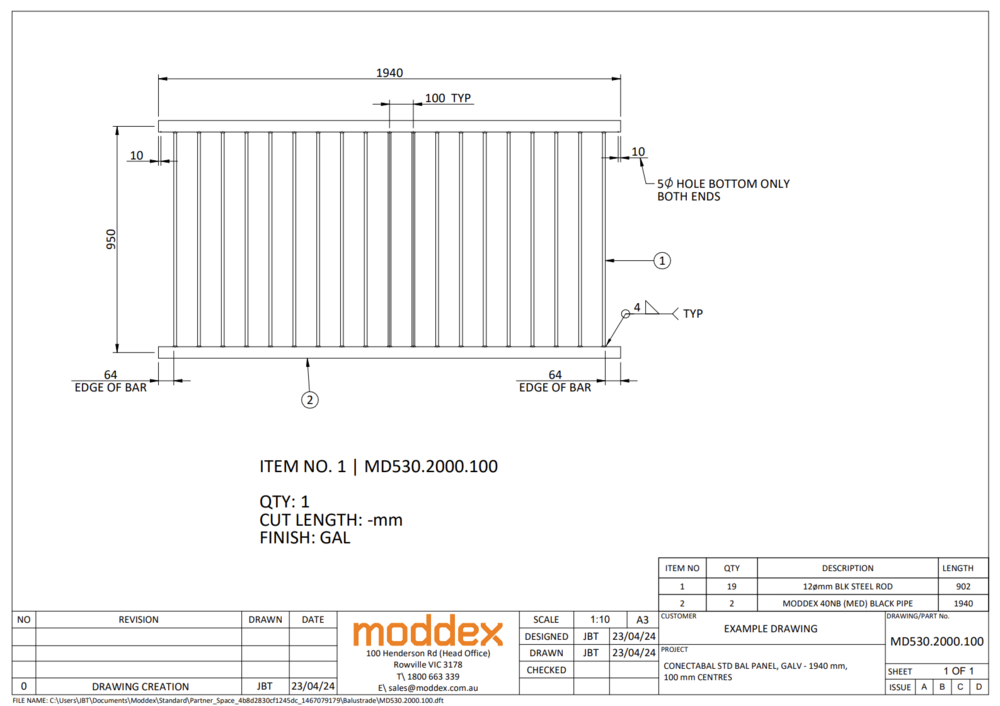

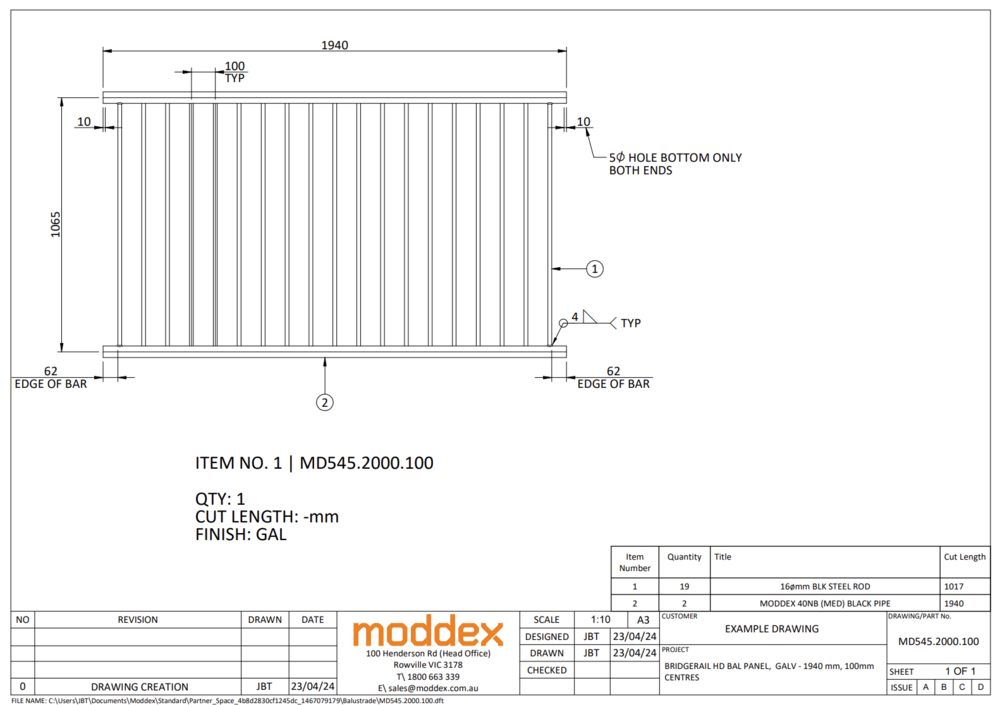

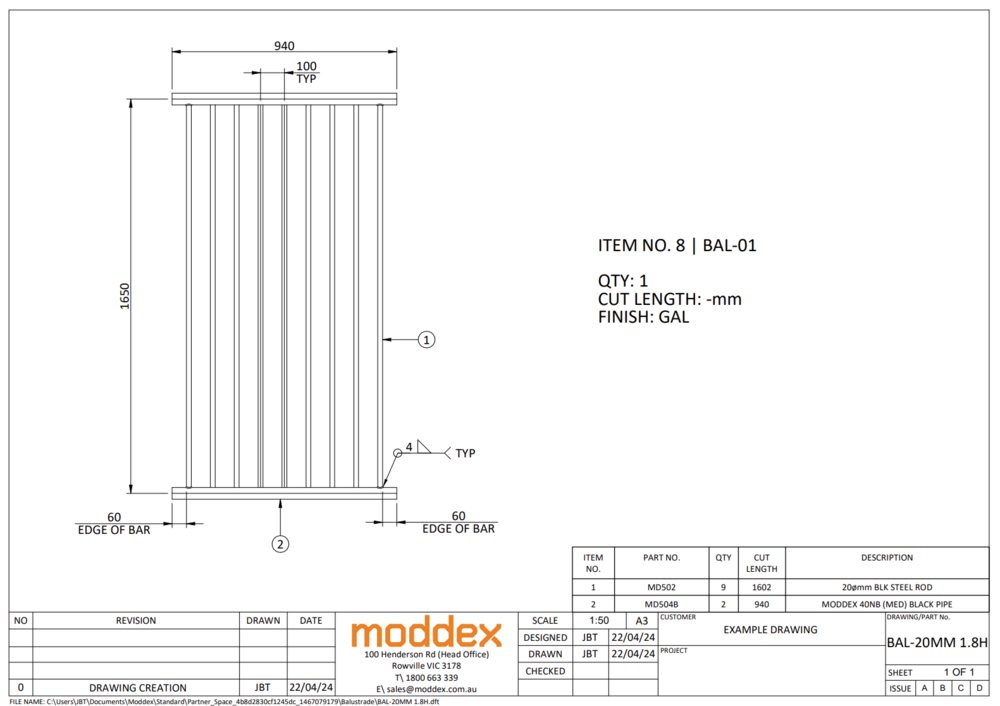

On balustrade panels, regardless of rod size (12, 16, 20mm), we will always use a typical (TYP) 4mm fillet weld all-round. Below are example drawings of 12mm, 16mm & 20mm rod panels.

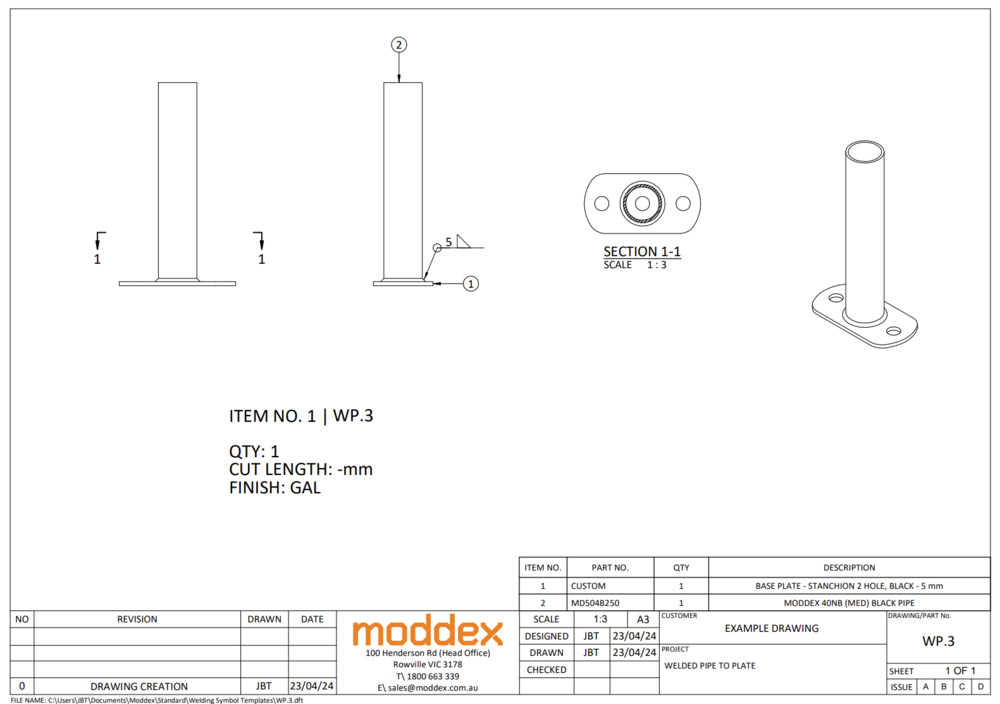

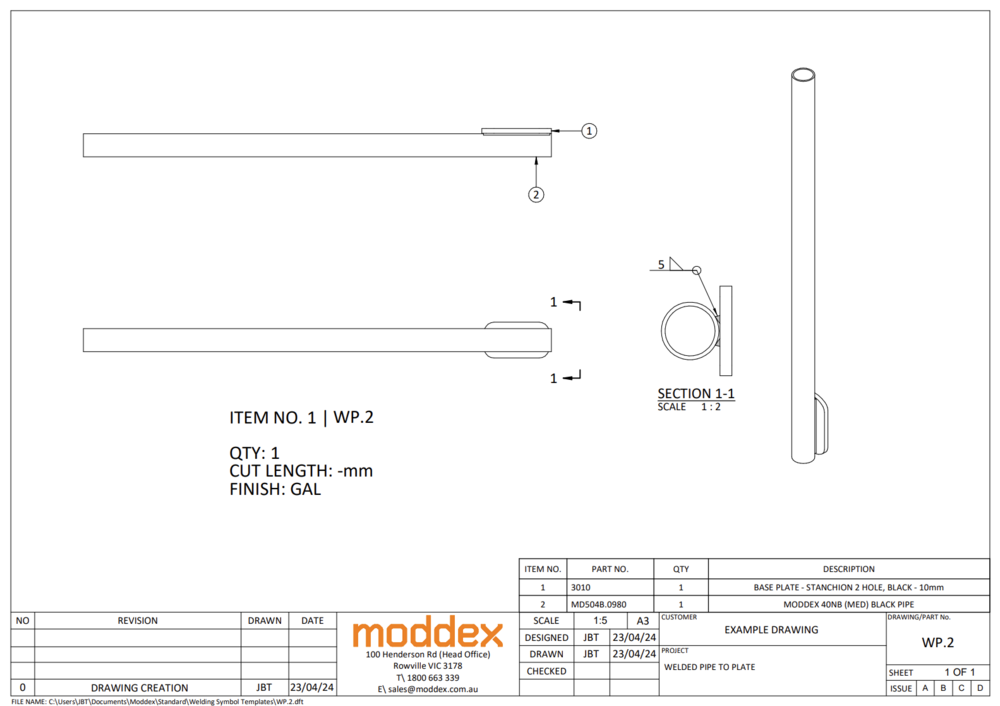

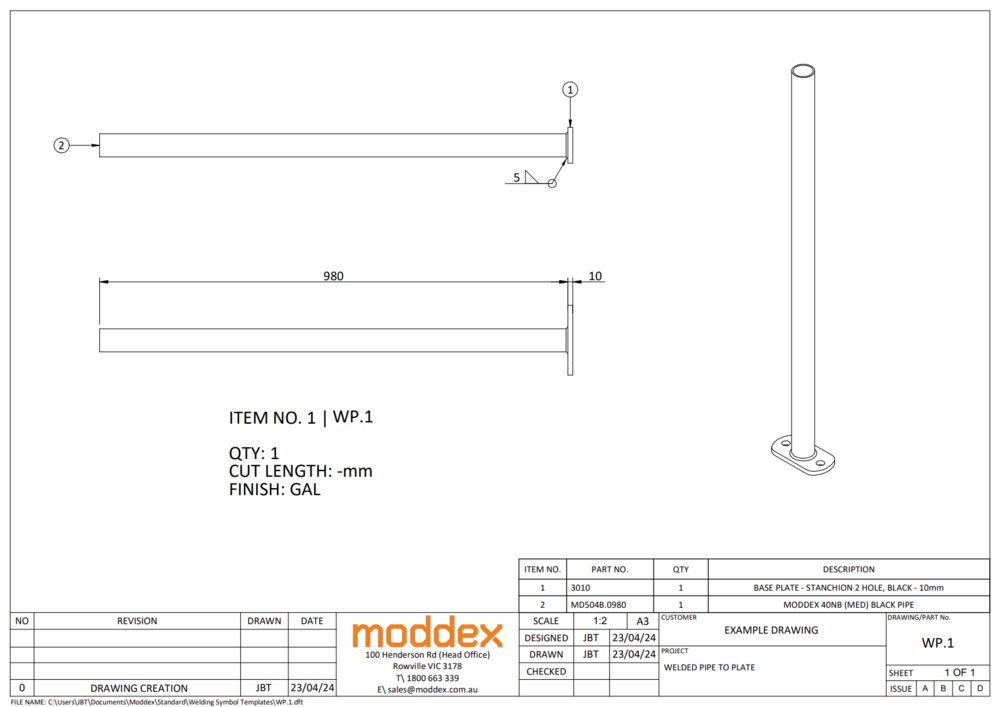

Pipe to Plate

When welding plates to pipe, a 5mm fillet weld all-round is used. Below are example drawings of different orientation & sizes of plates welded to pipe.

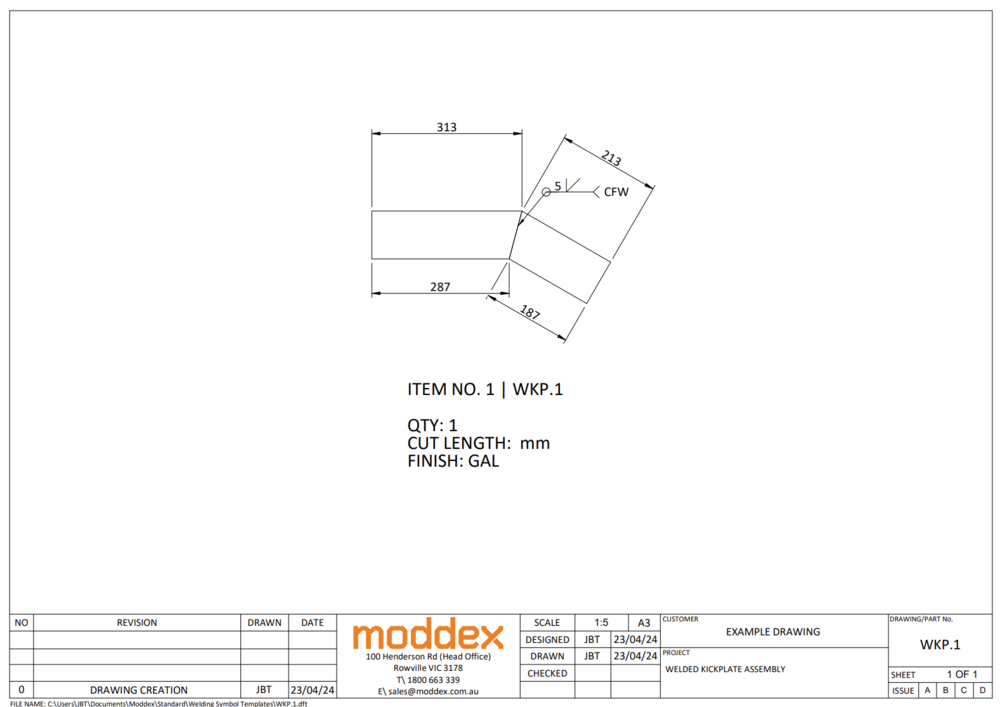

100x6 Kickplate

100x6 kickplate requires a 5mm bevel butt, continuos fillet weld (CFW) all-round. Below is an example drawing showing this.

Rail to Rail

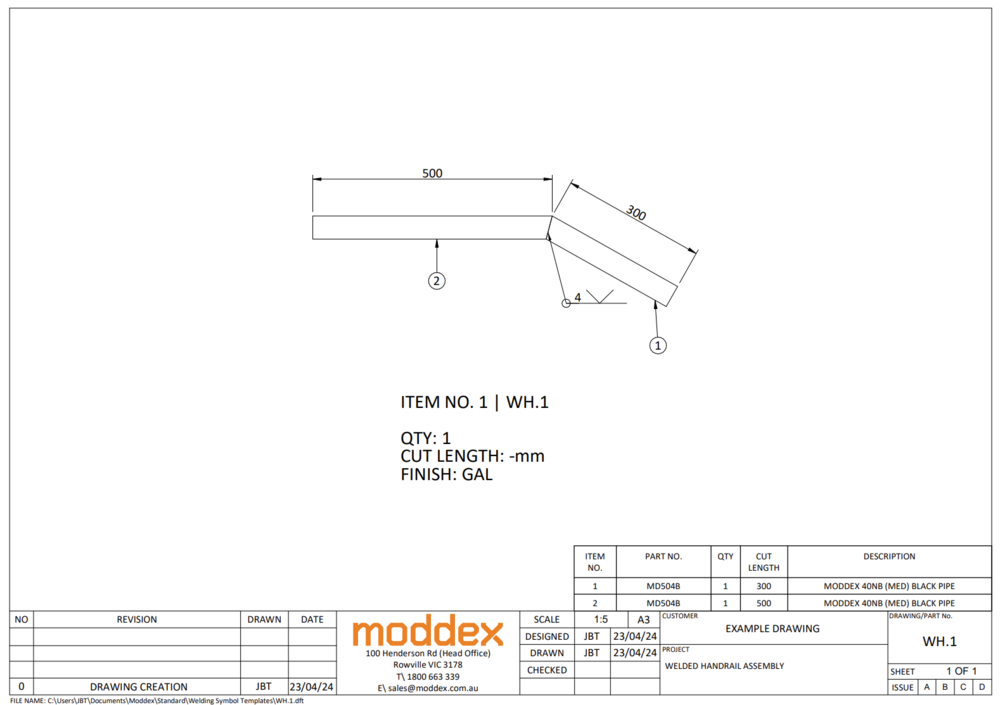

When welding pipes directly to other pipes, a 4mm V butt weld all-round is required. This symbol is used on such items as welding mitred pipes or welding 3300/UFJ90-40 to pipes for balustrade panels.

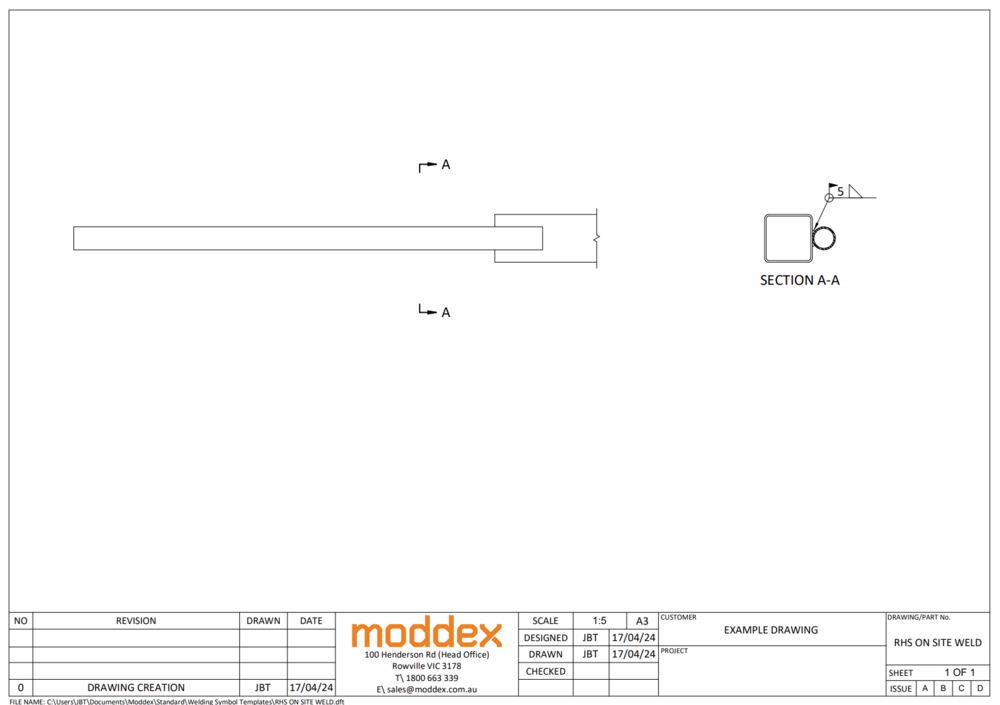

On Site Weld (ID)

The symbol shown on the drawing below (5mm fillet weld all-round) represents a requirement to site weld, rather than weld in house. This particular symbol would only appear in our installation drawings (ID).

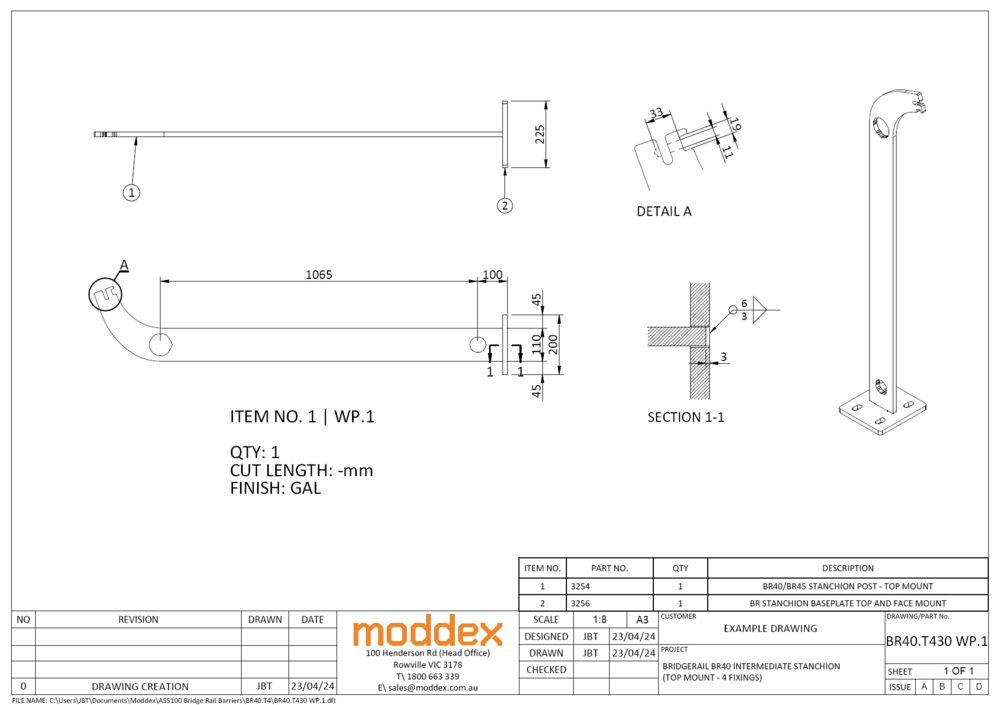

BridgeRail Welded Post

With our BridgeRail posts a larger weld is required due to the plate thickness & also for increased strength. The symbol below represents a 3mm & 6mm fillet weld all-round. Take note however, the location of where the arrow is pointing to on the drawing & which side of the symbol the number is on, is crucial. The arrow is pointing to the underside of the post, so this will be the first area welded. The upper number on the symbol is the first weld to be completed, so this will be a 3mm fillet weld all-round. On the opposite side of where the 3mm fillet weld is, is where the 6mm fillet welded all-round will be.