Main Page: Difference between revisions

| Line 70: | Line 70: | ||

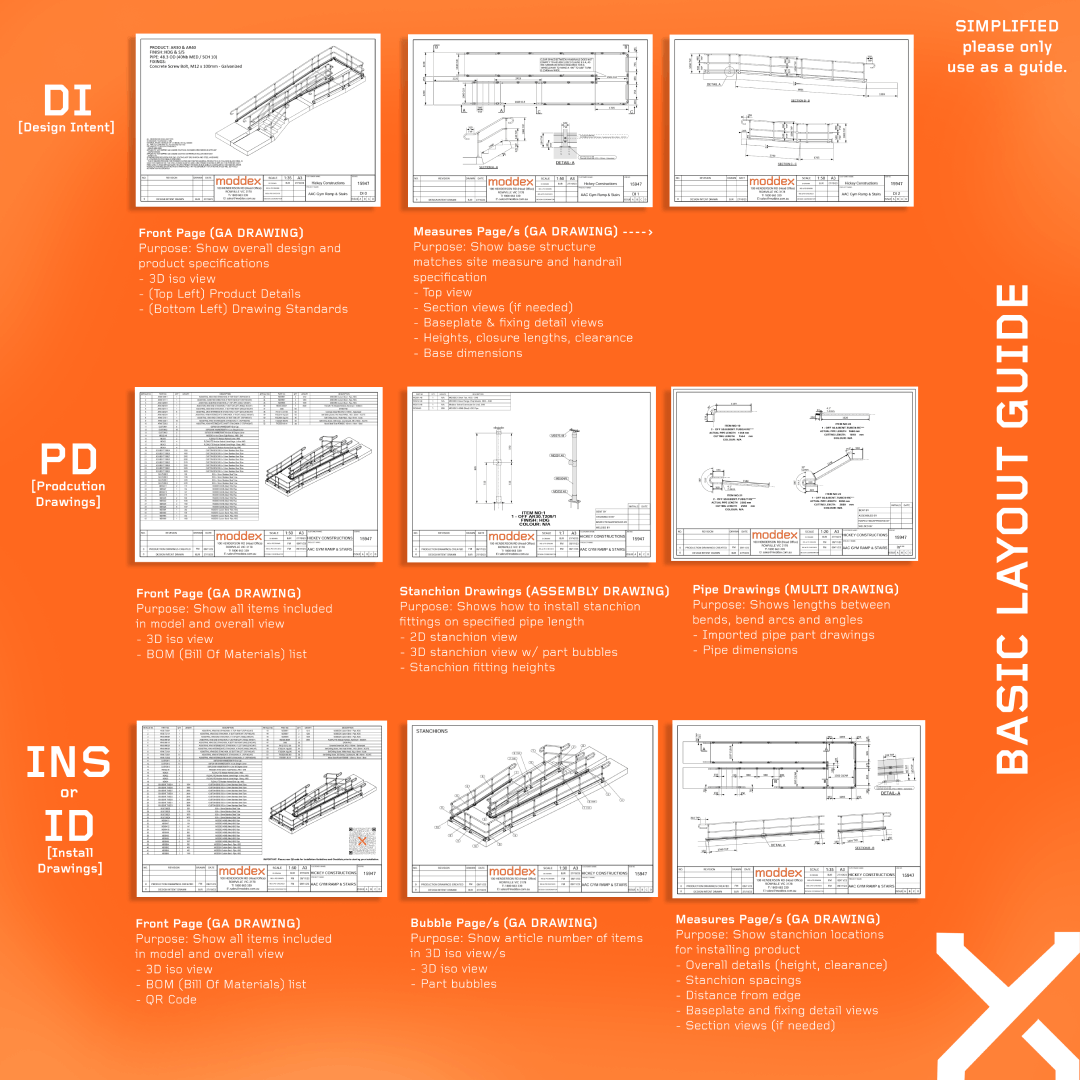

[[Example Drawings|Provided here are example drawings that can be used as a reference when creating DI/PD/FAB/Rolled pages]] | [[Example Drawings|Provided here are example drawings that can be used as a reference when creating DI/PD/FAB/Rolled pages]] | ||

<div class="toccolours mw-collapsible" style="width:1900px; border:none; background-color:transparent; overflow:auto;"> | |||

<div class="mw-collapsible-content"> | |||

<div | |||

[[File:Basic Drawing Layout Guide Resize.png]] | [[File:Basic Drawing Layout Guide Resize.png]] | ||

</div></div> | |||

===Pipe Types=== | ===Pipe Types=== | ||

Revision as of 22:40, 7 February 2024

Welcome to the Moddex Wiki

The Moddex Wiki is a comprehensive resource for information on all of Moddex’s products and systems. It contains detailed product information, Australian standards, Moddex standards, tutorials, and general rules that we follow.

This Wiki is still a work in progress, please feel free to peruse this wiki and give any feedback to this email here.

Handrails, Barriers, and Balustrade

Moddex covers a range of different products suited to various different needs

- AssistRail - Disability Handrail

- Conectabal - Commercial Balustrade

- TuffRail - Industrial Handrail and Barriers

- Bikesafe - Bikeway Barriers

- Bridgerail - Bridge Barriers

For information on our range of fittings, please view the Quick Find Guide

For information on our range of fittings, please view the Fixings page.

Design

Tutorials and Training Material

As of December 2023, there has been work on new training reference material for new and existing drafters.

These tutorials are made to help assist new drafters with learning the basics of drafting Moddex products in Tekla.

There are also more advanced tutorials to help even experience users to refresh on some of the less used processes in Tekla.

All training material can be found here.

Rail Standards

At Moddex, we are committed to delivering high-quality and safe rail products that meet the needs and expectations of our clients. To achieve this, we have to follow the Rail Construction Standards that are applicable to our projects, such as the Australian Standards, the Rail Industry Safety and Standards Board (RISSB) Standards, the National Construction Code, and the Disability (Access to Premises – Buildings) Standards. These standards provide the design, construction, and installation requirements for fixed platforms, walkways, stairways, ladders, and other rail infrastructure elements. By adhering to these standards, we ensure that our products are compliant, reliable, and accessible for all users.

For Australia this includes Australian Standards AS1428 for AssistRail and AS1657 for TuffRail.

Common Tasks & Terms in Drafting

- CADHS

The Computer Aided Design Handover Sheet (CADHS) is a document in all job folders that displays the product, fixing type and finish as well as any special considerations needed for drafting.

- Prefab

Used for automatically generating prefabricated steel and concrete structures such as ramps, stairs and curved walkways.

- Construction Line

Construction lines are used as a guide for creating custom base structures as well as custom pipes, panels and stanchions.

- Base Structure

The combination of all the custom concrete and steel beams as well as any prefabs. The base structure is constructed before any product is added.

- Measure

Used for measuring to snapping points, such as orthogonal points, horizontal and end points. Can also measure angles.

- Tracing Tool

The most common way to add Moddex product to a model. This tool is to be used on flat surfaces and complex stairs/ramps.

- Drag & Drop Tool

Another way to add Moddex product to a model. This tool should be used whenever there is a simple prefab.

- Stanchion

A post that supports the pipe or panels. Stanchions are given a specialized code depending on their purpose.

- Fixings

Fixings are the screws and bolts that attach a Moddex handrail to the base structure.

- Redraw

Used for deleting temporary graphics and refreshing views. If there are any visual problems with your model always redraw before asking for help.

- Green

An extra 150mm of material that is added to a pipe and cut off before being sent out to site. Green is always placed on the shortest end of the pipe. When creating a P&P green appears on the Pick list but not that pack list as the green is removed before being packed.

- Black

A finish required for all fabricated parts. Black finish means that there is no galvanization on the steel and therefore safe to weld.

- Numbering

Used for allocating part & article numbers to parts and pipe so they can be individually identified when installing and fabricating.

- Pick & Pack List

An excel document containing all the parts in a job. Pick lists show the base parts that need to be picked off the shelf before commencing a job and Pack lists show what parts need to be packed onto the pallet and sent to site.

Example Drawings

Pipe Types

| Pipe type | Associated Codes | Where it's applied | Description |

|---|---|---|---|

| Standard 40Nb | MD504 (Straight)

MD598 (Rolled) MD599 (Custom Bend) |

Most jobs | 40Nb pipe is the standard pipe used on products at Moddex.

40Nb pipe is steel/grade C250 that has a protective coating of G390 Hot-dip Galvanized. |

| Powdercoated

ZP & PC |

MDxxxPC

P & F (ZP & PC) PO (ZP & PC) |

Powdercoat can be applied to jobs on customer request | ZP & PC is used on black pipe. The pipe is sprayed with Zinc Prime (ZP) and then powdercoated (PC).

P & F stands for Pipes and Fittings PO stands for Pipes Only |

| Powdercoated

HDG & PC |

MDxxxPC

P & F (HDG & PC) PO (HDG & PC) |

Powdercoat can be applied to jobs on customer request | HDG & PC is used on pipe that has been or will be hot-dipped galvanized (HDG), and then gets powdercoated (PC).

P & F stands for Pipes and Fittings PO stands for Pipes Only |

| Green | N/A | Used for when creating bent pipe that has a tail less than

170mm or a front less than 50mm |

Green essentially means additional pipe length which is used on pipes that won’t be able to be bent in the bender.

Green is also used on rolled pipes to allow the machines to roll the pipe. |

| Black | MD504B (Straight)

MD598B (Rolled) MD599B (Custom Bend) |

All fabricated products | Black is applied to any pipe that is going to be fabricated. This pipe has not yet been galvanized.

Black pipe is steel/grade C350. |

| Rolled | MD698-10 (Stainless Steel)

MD598 (HDG) MD498.T4 (Aluminium) |

Used typically on any curved surface

Examples includes footpaths, skateparks, and silos |

Rolled pipe/tube is outsourced and not rolled by Moddex. Because of this, rolled pipe/tube has its own booklet that is

sent to the company that’s outsourced. Rolled pipe/tube has an additional 300mm of green on both ends, this is so that it can be rolled. With double span TR we can use a MD201.48 as a top fitting to allow the rolled pipe to run through, as long as the rolled pipe doesn’t have a dramatic radius. |

| Aluminium | MD404.T6 (Straight/Stanchion)

MD498.T4 (Rolled) MD499.T4 (Custom Bend) |

Aluminium can be applied to jobs on customer request | Aluminium pipe comes in 2 different aging processes, T6 which is used just as straight pipe, and T4 which is used for

rolling and bending. Jobs using aluminium pipe will need to also use aluminium 300 series fittings. |

| Stainless Steel | TUFFRAIL

MD604 (Straight) MD698 (Rolled) MD699 (Custom bend) Other 50.8.TUBE.LENGTH (Straight) 50.8.ROLLED.LENGTH (Rolled) 50.8.BEND.LENGTH (Custom Bend) |

Stainless Steel can be applied to jobs on customer request | When used with TUFFRAIL, stainless steel pipe is used at a diameter of 48.3mm

With this size pipe, Moddex 600 series fittings are used. When used with ASSISTRAIL, stainless steel tube is used at a diameter of 50.8mm x 1.6mm Stainless Steel tube will need to use custom fittings (Hammersmith) as Moddex does not supply standard parts for this type of tube. |

| Heavy Duty | MD504HD

MD504.6500HD MD504B.6500HD |

Stanchions that are supporting CB panels with an overall

height equal to or larger than 1500mm |

Heavy Duty pipes are only used as stanchions and can fit standard Moddex 100 & 200 series fittings. |

| 50Nb | MD505 (Straight Med)

MD505H (Straight Heavy Wall) MD505R (Rolled Heavy Wall) MD509H (Custom Bend Heavy Wall) |

Top rail of Bridgerail | 50Nb is used mainly as the top rail of Bridgerail to follow AS5100, standard bridge design. |

| 32Nb | MD503 (Straight)

MD592 (Rolled) MD593 (Custom Bend) |

32Nb pipes are used mainly in AR jobs that involve VIC

primary schools which also means it has a max rail height of 880mm, and if a lower handrail is required, 680mm |

32Nb pipe are only used as handrail, not stanchions. They have their own pipe fittings that are standard Moddex parts.

In schools we only use 32Nb on double rail systems, this includes; AR110, AR120, AR130, AR140, AR160, CB50, and CB55. |

| Extra Light | MD504.6500XL | Used for extending MD201.48 and MD748.42 as a combo | Extra light pipe is used in-between a MD201.48 and MD748.42 to extend the swivel railing bracket out when required. |

Moddex Job Categories

| MODDEX JOB CATEGORIES | |||

|---|---|---|---|

| CATEGORIES | DETAILS | DESIGN (DI Leadtime) | PRODUCTION |

| CAT 1 | BOM - Job Picked off the shelf stock items (including pre-assembled stanchions) | 2 | |

| CAT 2 | BOM - Items picked, custom bent pipe (inhouse) and assembled to order (no custom fab) up to 30k | 3 | |

| CAT 2d | As Above - With Design, including standard Ezbilt ramps (base only) | 2* | 6 |

| CAT 3 | BOM - Items picked, custom bent pipe (inhouse) and assembled to order (no custom fab) Over 30k | 3* | 8 |

| CAT 3d | As Above - With Design | 4* | 8 |

| CAT 4d | Job requiring rolled pipe, custom fab & galvanising/coating up to 30k - With Design | 5* | 10 |

| CAT 5d | Job requiring custom fab & galvanising/coating over 30k - With Design | 7* | 12 |

| CAT 6d | Fully Fabricated products requiring subcontract manufacture, laser cutting & galvanising/coating - With Design, Example AS5100, EFSG - up to 80k | 10* | 25 |

CAT 6d over $80k, to be discussed with a project manager

Please note: These leadtimes are based on jobs being able to be released to Design & Production, where nothing can prevent the work being undertaken (missing details, not enough information, payment/accounts issue etc)

Departments

| Role | Name | What Is The Role's Responsibilities? | |

|---|---|---|---|

| SALES DIRECTOR | Joe Rowland | ||

| Queensland | |||

| State Manager | Sam Eade | ||

| Area Manager | Ed Archer | ||

| Business Development Supervisor | Mirella Pastega | ||

| Project Consultant | Ronnie Reoch | ||

| Personal Assistant | Jessica Stead | ||

| Customer Support | Debbie Nicolai | Layla Stiler | |

| Customer Services Assistant | Claudia Rowland | ||

| Estimator | Tony Weaver | ||

| Victoria | |||

| Ramp Program Delivery Manager | Rick Parbery | ||

| Senior Solutions Engineer | Ali Mahdieh | ||

| Project Consultant | Amos Williams | ||

| Project Consultant | Kaine Jamieson | ||

| Customer Service Assistant | Brodie Jamieson | ||

| New South Wales | |||

Production Team

CAD Design Teams

Australia, Design Academy

Design Manager

- Clayton Weideman

Design Team Leader

- Ryan Simpson - RS

Design Team Coordinator

- Iain Simpson - IS

Design Coordinators

- Aden Corke - AJC

- Gavin Wootton - GW

Design Scheduler

- Blake Napier - BN

Mid-Developer

- Clancy Lewis - CL

Junior Software Developer

- Caleb Worth - N/A

CAD Drafters

- Kye Bryce - KLB

- Ben Dalglish - BJD

- JP Lowe - JPL

- Cruise McClounan - CM

- Ford McClounan - FM

- Aaron Nehow - AJN

- Anthony Russell - AWJR

- Bruce Russell - BJR

- Ben Simpson - BS

- Annabelle Thomas - AT

- Peter Tucker - PT

- Tom Wilmshurst - TW

- James Wong-Kam - JWK

New Zealand

Design Coordinators

- Adrian Cousins - APC

CAD Drafters

- Jakob Eder - JLE

- Caleb Philips - CP

Consult the User's Guide for information on using the wiki software.