Important Updates: Difference between revisions

No edit summary |

No edit summary |

||

| (112 intermediate revisions by 7 users not shown) | |||

| Line 1: | Line 1: | ||

This page includes direct information and updates about products, fittings, fixings, design updates, and any other relevant information that the Design Academy drafters will need to use. This information will usually be copied directly from emails received from Ryan or Iain. | This page includes direct information and updates about products, fittings, fixings, design updates, and any other relevant information that the Design Academy drafters will need to use. This information will usually be copied directly from emails received from Ryan or Iain. | ||

==02/06/2023== | =2025 Updates= | ||

==24/10/2025 - Updates to Kliptread Fixings== | |||

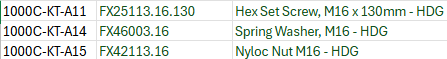

Kliptread fixing codes have been updated to the following (Black: old code, Green: new code) | |||

[[File:Kliptread Fixings.png|500px]] | |||

==2/10/2025 - MD580 Panels cannot be tweaked== | |||

Any panels to suit 1500mm high balustrade cannot be tweaked & have to be fabbed. The benches for tweaking aren’t big enough but the main issue is the 16mm bars make it harder to do so. Please keep this in as anything angled will be required to be on the FAB PDs & the parts in the pick/pack to make the panels. | |||

==30/09/2025 - MD768L - Custom bracket for CB20 Top Mount== | |||

We now have a code for the longer MD768 bracket when Tuffgard is used on CB20 Top Mount. For other mounts we can still use the MD298.48 mounted upside down as there is clearance between the baseplate & bottom of the panel. | |||

==26/09/2025 - 3300 welds on panels== | |||

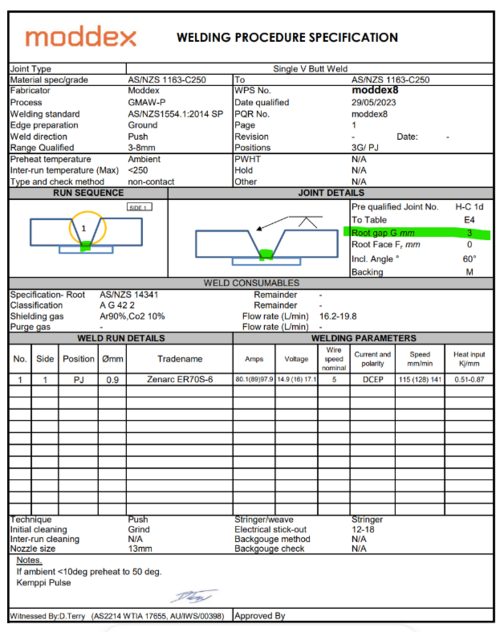

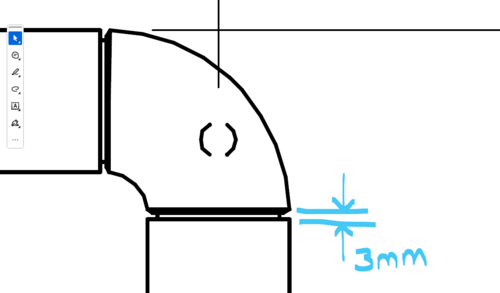

Part of our welding procedure when using 3300 elbows requires a 3mm gap between the fitting & the pipe. Moving forward can you please include this in your models which will allow production to follow the correct procedure & not having to trim pipes down. For those using Tekla this should be automated already in the plug-ins but for those not you will need to allow for this. | |||

[[File:3300_Weld_Page.png|500px]] | |||

[[File:3300_3mm_gap.png|500px]] | |||

==01/09/2025 - New Core Depth in WA== | |||

In WA our standard core depth is now 350mm into the ground. In WA when we core mount its normally into limestone blocks which are 350x350mm, so this depth puts us as far into the block as we can go. | |||

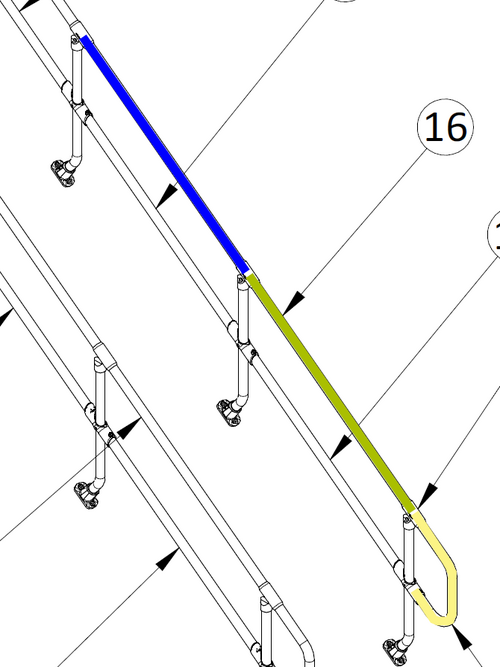

==21/08/2025 - New Bend To Add Green To== | |||

On the bend below, we need green at the end. The type of bend needs to be done different than normal so the green is required at the end of the bend. It’s only required where there is a small bend at the end of it. | |||

[[File:New Bend Green.png|500px]] | |||

==8/08/2025 - New MD201.48 Design== | |||

A new update to the design of the MD201.48 has been released. The shape is different to allow it to go around 90° bends. There is a design issue though with the stop in the fitting for pipe/panels coming in. This means standard panels will need to be cut down & that we can't use MD504.1940 pipe on end stanchions where this is used. The design will be fixed in REV4 & we will advise once that has been released. | |||

==23/07/2025 - New weld-in elbow - 3300.REV03== | |||

Moving Forward, the new weld-in elbow for panels & handrails needs to be 3300.REV03. This supersedes the UFJ90-40B | |||

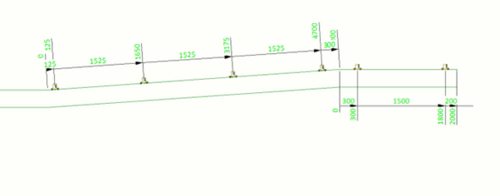

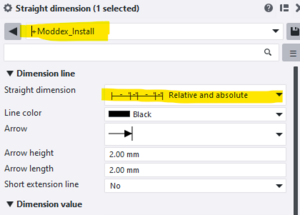

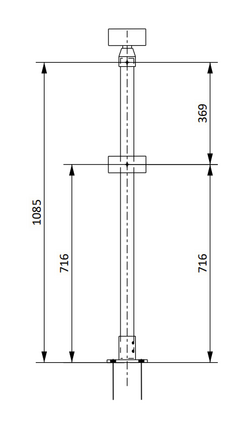

==22/07/2025 - New Dimension Standard for Install Drawings== | |||

Moving Forward, install drawings will need to show both the relative and absolute dimensions for stanchion positions. This will show both the rolling dimension from 0, as well as the centre-to-centre dimensions. | |||

[[File:Running Dim.png|500px]] | |||

In the properties pane, choose the +Moddex_Install option from the presets, or alternatively, select Relative and Absolute from Straight dimension field. Ensure that your firm folder has been updated using Trimble Connect Sync. | |||

[[File:Screenshot_2025-07-22_113637.png|300px]] | |||

==24/06/2025 - New Pick/Pack== | |||

We’ve made a few improvements to the pick/pack list to make life a little easier for production. | |||

1. The pick & pack list now has colours in some of the columns. This is used just to remind production that they need to be filled out. | |||

2. There is a new tab called Rods Report. This needs to be used when we have custom fab panels as production will cut the rods without needing to look over the drawings. | |||

a. Rather than compiling all lengths of round bar into full lengths, with a quantity, they want it broken down into cut lengths & quantities. | |||

b. With the angle, only note that if there is an angle, both top & bottom. If there is an angle on 1 side of the rod, don’t note it & it can be trimmed to suit before it is welded in. | |||

c. All angled bars, measured from long to short (so along 1 side of the bar). | |||

d. If only one end is angled, measure to the longest end. | |||

3. We will still need to include the total QTY of round bar in the pick list, as we still do now, as this is used to take stock out of the system. | |||

4. Please include the item number on the rod report. | |||

==23/06/2025 - New Stanchion Runnings Dimensions== | |||

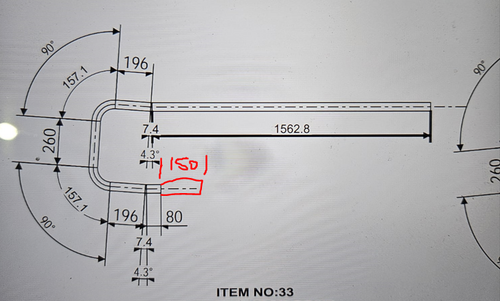

The below photo is a snip of a stanchion from Tekla. Production has requested that we include the running dimensions on the right of the snip on all our drawings from this point forward. | |||

[[File:Running_stanchion.png|250px]] | |||

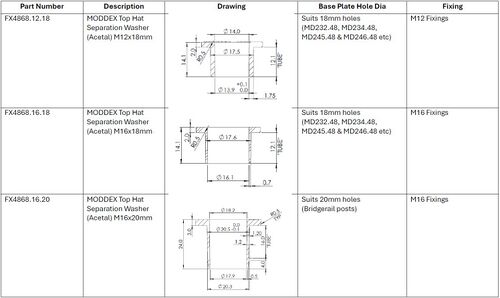

==11/06/2025 - Top Hat Washer Differences== | |||

Below is a photo showing the codes, descriptions & where each washer gets used. | |||

[[File:Top Hat Washers.JPG|500px]] | |||

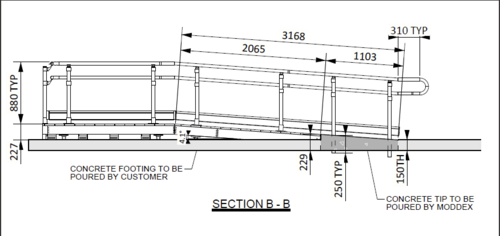

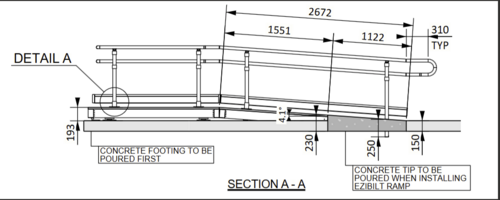

==22/01/2025 - Ezibilt - detailing Ramp Tips== | |||

The notes need to be as per the below when the job is supply only. If you have any questions please reach out. | |||

Moving forward we need to add extra detail to our Dis & Install drawings for Ezibilt regarding the concrete ramp tip. Please keep the attached drawing as an example but essentially the customer pours that slab for us to mount on & the ramp tip is poured by our installers. We need to always have the below few points on the drawing. | |||

Posts on the ramp tip to be inground 250mm | |||

Ramp tip to be 150mm thick at it’s lowest side | |||

Ramp tip & concrete to be shaded but different colours to make it obvious | |||

Notes on the drawing stating who is pouring what | |||

Moddex to pour ramp tip | |||

Customer to pour concrete for footings | |||

Dimensions from a datum showing where the tip is located | |||

If you have any questions or what your drawings checked while doing them please reach out. | |||

[[File:Extra Ramp tip detail 1.png|500px]] | |||

Further to this, the notes about Customer & Moddex pouring sections of concrete only apply if we are installing. You should be able to tell on the CADHS if we are installing but if you are unsure please ask myself or another DC. | |||

The notes need to be as per the below when the job is supply only. | |||

[[File:Ramp tip notes.png|500px]] | |||

=2024 Updates= | |||

All important updates sent in 2024 | |||

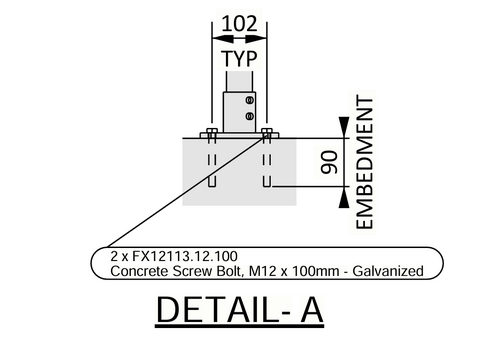

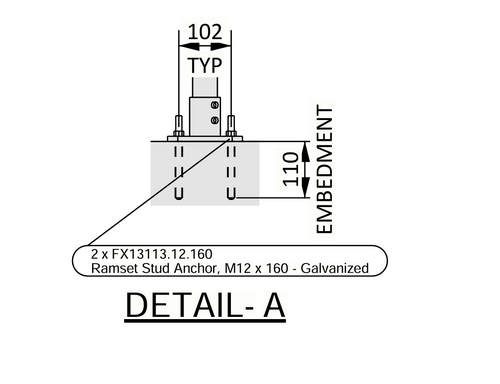

==11/12/2024 - Embedment depth on DI's & Installs== | |||

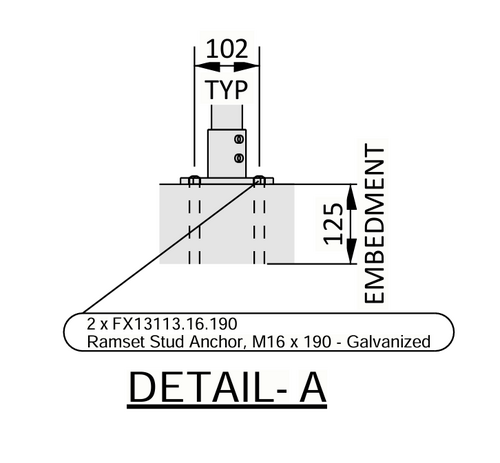

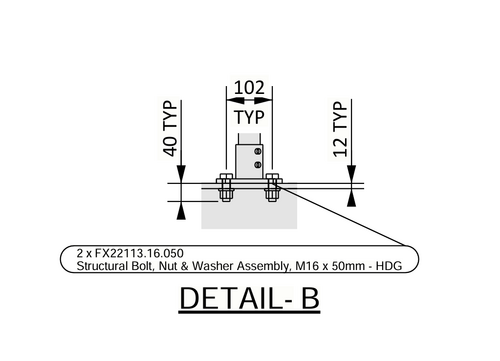

We need to start showing our embedment depth on Design Intent & Install drawings. Below are some examples of what we need to show and the correct embedment's for different fixing types. When mounting to steel please detail the thickness of the steel we are mounting into & the length of the bolt. | |||

[[File:Conc em.png|500px]] | |||

[[File:160 em.png|500px]] | |||

[[File:190 em.png|500px]] | |||

[[File:Struc em.png|500px]] | |||

==02/10/2024 - Designing Powder Coated Aluminium jobs== | |||

Moving forward with powder coated Aluminium Tuffrail jobs, please design your rails as single span. There have been issues reported with the pipes not running through fittings or scratching. Example images below. | |||

[[File:Al Tuffrail 1.png|500px]] | |||

==24/09/2024 - Flexalyte and Tuffgard - Radius achievable without rolling== | |||

We've done some testing to see how much our Flexalyte & Tuffgard can be pulled around a curve to avoid rolling. Flexalyte has increased to a radius of 10000mm. While for Tuffgard it is now currently sitting at 3000mm without rolling. | |||

==10/06/2024 - Change to UFJ90-40B from 3300== | |||

We have to change from our 3300 weld-in elbows to a new design for the UFJ90-40B. Please start drawing this in now as stocks of 3300 are getting low. | |||

==10/06/2024 - Weld Symbols on Drawings== | |||

Good Morning team, to improve our processes & help out production, we now need to start including weld symbols to our fabrication drawings. | |||

Weld symbols are a representation of the type, size, finish & process of a weld, all bundled up into an easy to read, nationally recognized symbol. This was not something we used to do previously, however it will be a huge improvement to our drawings. This will also be an improvement for any out-of-house company that we provide drawings for welding, as they will now have a clear understanding of the welds we require. It also covers our butts, in the case that something is not welded to the spec we specify. | |||

Below is a link to the Moddex Wiki, with a dedicated page to weld symbols. The page contains details on understanding what a weld symbol is, example production drawings containing different types & sizes of welds & their associated symbols with explanations & also some instructions on how to create weld symbols within Tekla (make sure to click on the [Open] text on each sub heading, this will show the drawings). Over the next couple of weeks I’ll also try & add in instructions for Solidedge & Solidworks as well. | |||

http://20.211.196.52:8080/index.php/Weld_Symbols | |||

I’ll have a this added to the Master CAD Checklist also. If you have any questions or want some training I am free to help. | |||

==04/06/2024 - Adding more details into Project name titleblock== | |||

Hi all, | |||

A recommendation from sales was to add more details in our title blocks regarding the project name of a job. Below are 2 examples of what they are after. This is mainly for the bigger jobs with multiple sections to make it easier to know what you are looking at. If you are unsure of what to name your drawing, it is something noted on the customer's drawings or markups. | |||

(ADD PICTURES LATER) | |||

==03/06/2024 - MD251 & MD252== | |||

We now have stock of MD251 & MD252 | |||

It’s been found out that we have been using an old model of our stair baseplates for 2 or so years | |||

Models can be found at: \\design-academy\Reference Parts | |||

==16/05/2024 - New pick/pack template== | |||

Hi all, | |||

We have added 2 extra tabs to the pick/pack list. Please put them in order as per the attached. | |||

The Auto Saw Cut List is to be left blank & is to be filled out by production if/when required. This is just to be copied from this template into the pick/pack you create. | |||

The customer delivery note is to be a copy of the pack list but this is for the customers to fill in when receiving the product on-site. For those using Tekla there is a new report template for this as per what I’ve circled below. @Hansel let me know if your team doesn’t have this. | |||

For those in SolidEdge/Works you’ll need to copy what’s in the pack list to the customer delivery note tab. | |||

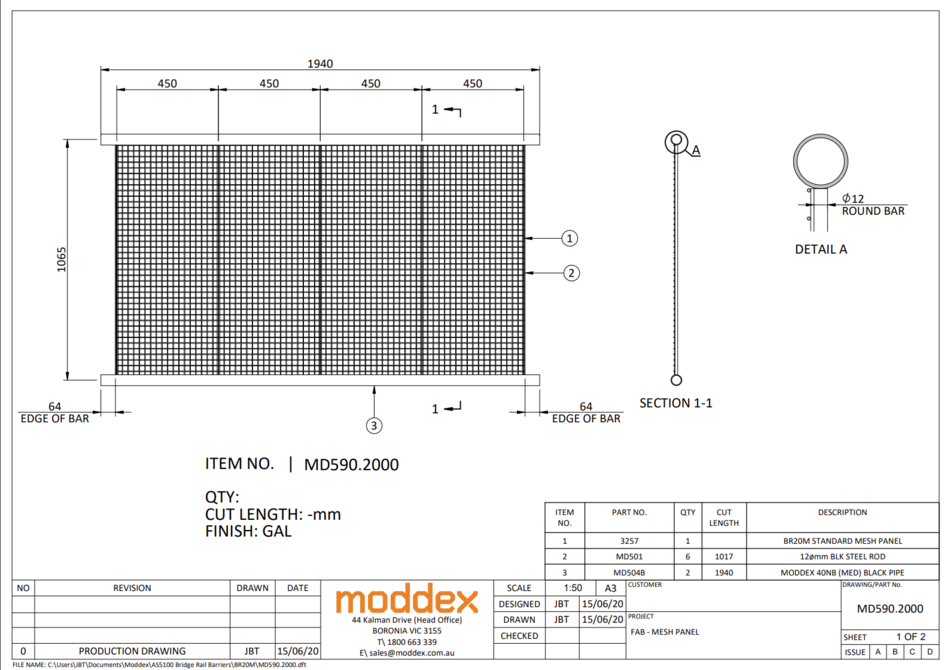

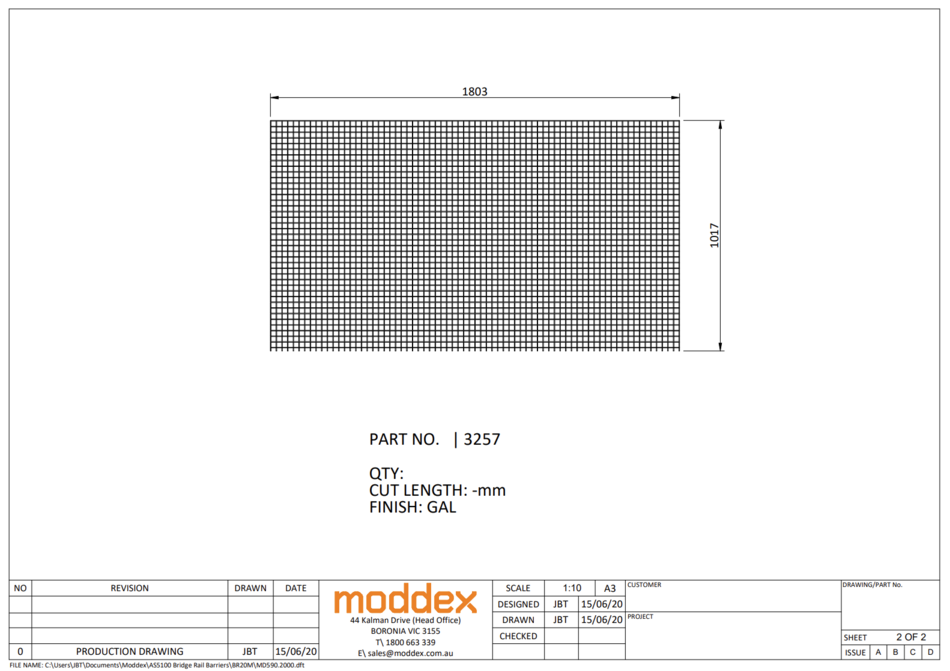

==12/04/2024 - Detailing for Mesh Panels== | |||

Hi all, | |||

When it comes to detailing mesh panels on PDs please follow the attached to avoid any issues when it is fabricated. | |||

Also, the mesh needs to face inwards towards the path, ramp & stair & the rods are behind that. | |||

If you have any questions please reach out. | |||

Regards, | |||

[[File:IU2.PNG|frameless|950px]] | |||

[[File:IU3.PNG|frameless|950px]] | |||

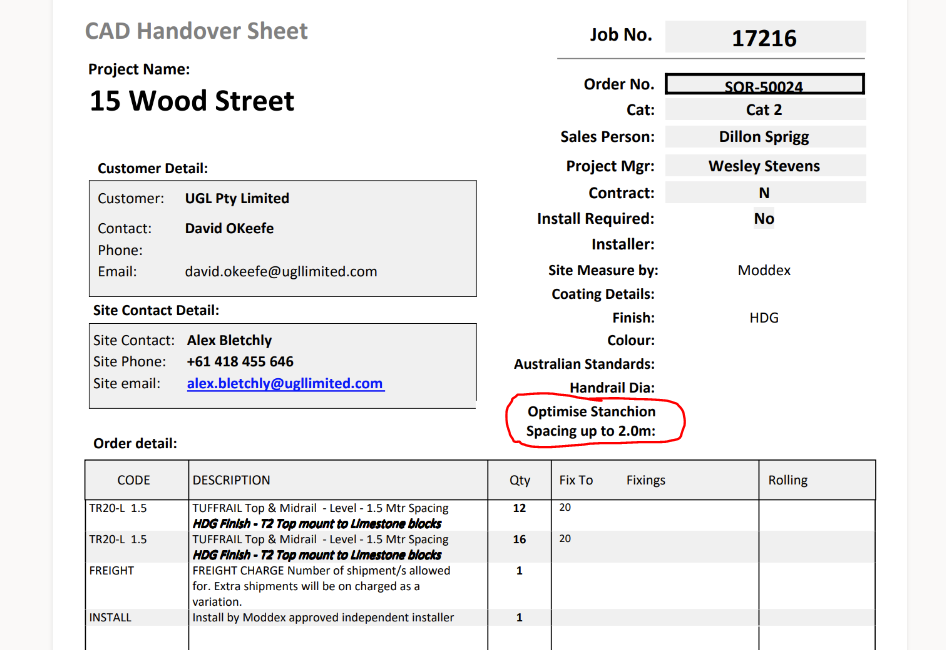

==12/04/2024 - Optimising Stanchion Spacings== | |||

Hi all, | |||

You’ll see below on new CADHS’s that new text that I’ve circled below. What this means is even if the job has been quoted as 1 or 1.5m spacings we can extend up to 2m with no issues. Sales sometimes reduce the spacings when quoting to bump up the price but we aren’t getting those wins if we follow that. | |||

It will either be Yes or No. If you have a job where it isn’t put in, please reach out & we’ll confirm what to do. | |||

Hopefully this makes sense but if you have any questions please reach out. | |||

[[File:IU1.png|frameless|950px]] | |||

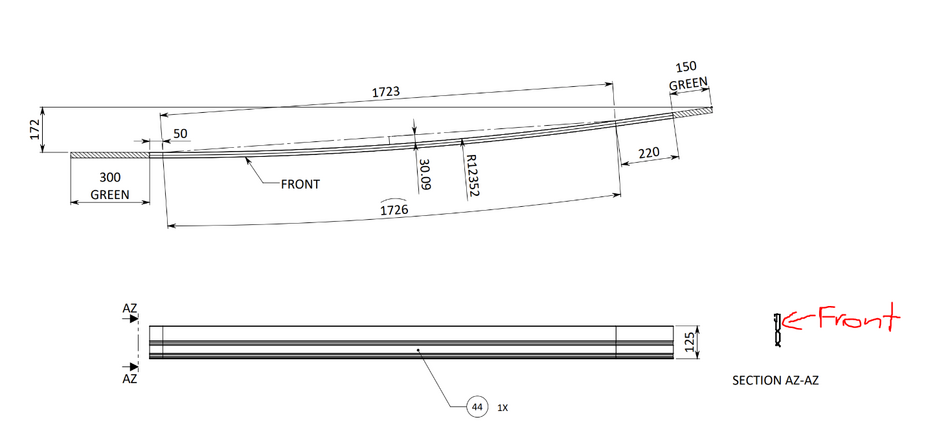

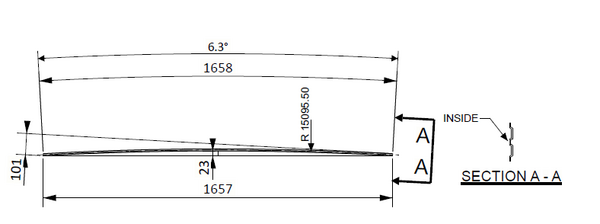

==11/04/2024 - Details on Curved Kickplate== | |||

Hi all, | |||

A request from production is to add in another leader not on the section view detailing the front, as I’ve sketched up. This will eliminate any confusion our rollers have in deciding which is the front/back. | |||

Please also make the section view (in this case AZ-AZ) larger so it’s easy to see the profile when it’s printed on an A4 sheet. | |||

[[File:Curved kickplate email example.png|frameless|950px]] | |||

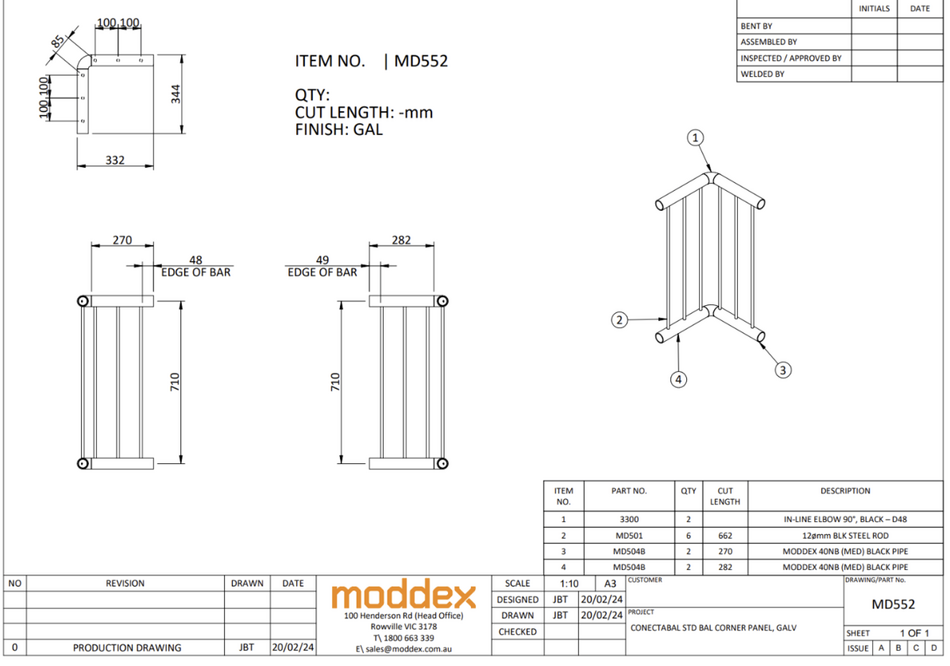

==11/04/2024 - 3rd Angle Projection== | |||

Hi all, | |||

We need to start detailing our fabricated panel in 3rd angle projection as per the attached. Only need to do these on 90°, 180° or funky design and isn’t required on a flat angled panel. | |||

Please also include the 2 below dimensions on 90° or 180° panels as this helps production they have made it correctly as it gives them something to double-check. | |||

If you have any questions please reach out. | |||

[[File:3rd angle example.png|frameless|950px]] | |||

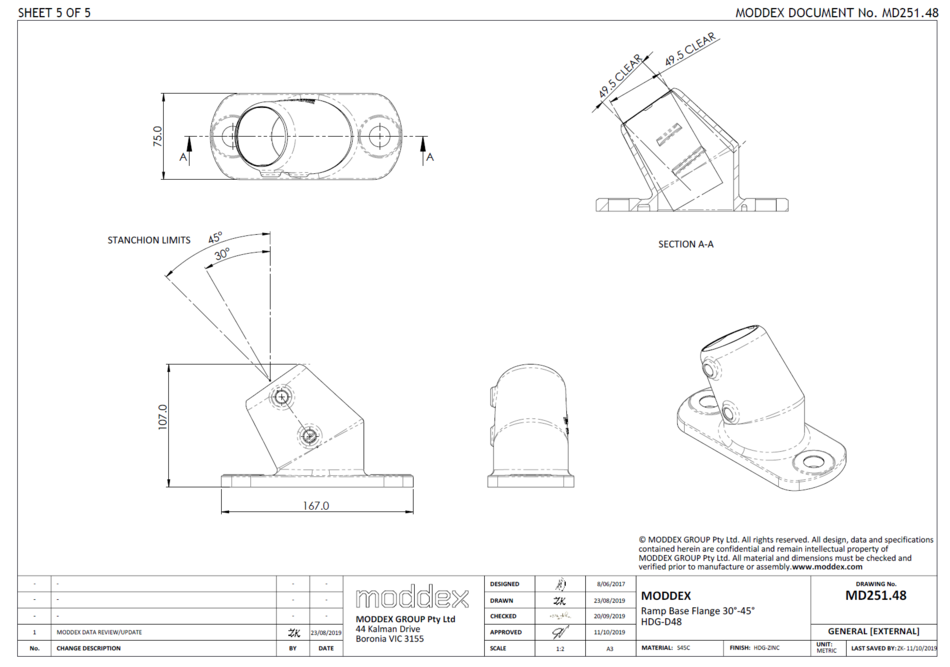

==09/04/2024 - RE: MD251.48== | |||

Hi all, | |||

We now have stock of our design for the MD251.48 so please use that rather than the old model. If you have any questions please reach out. | |||

[[File:MD251.48.PNG|frameless|950px]] | |||

Attached is the dimensions for the newer MD251.48 | |||

==09/02/2024 - 1200mm High Panels== | |||

<b>1200mm high panels</b> | |||

Just sending an email for these 2 panels to note where & when they are used. | |||

MD535 – 12mm bar (1050mm cnetres) | |||

*Gets used on normal CB products when they are required at 1200mm high | |||

MD545 – 16mm bar (1065mm centres) | |||

* Gets used on bridgerail jobs | |||

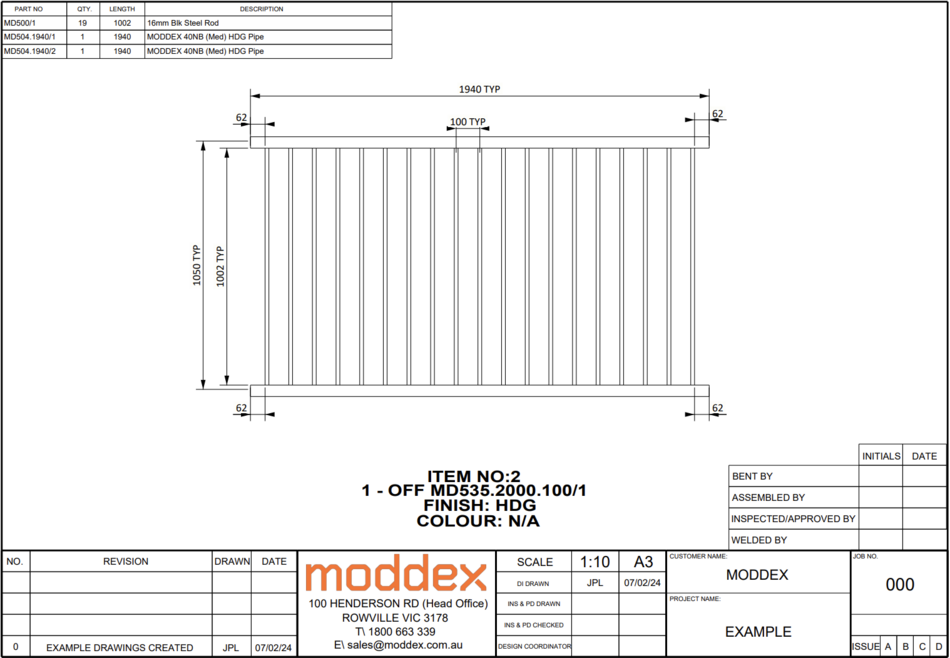

[[File:MD535.2000.100.PNG|frameless|950px]] | |||

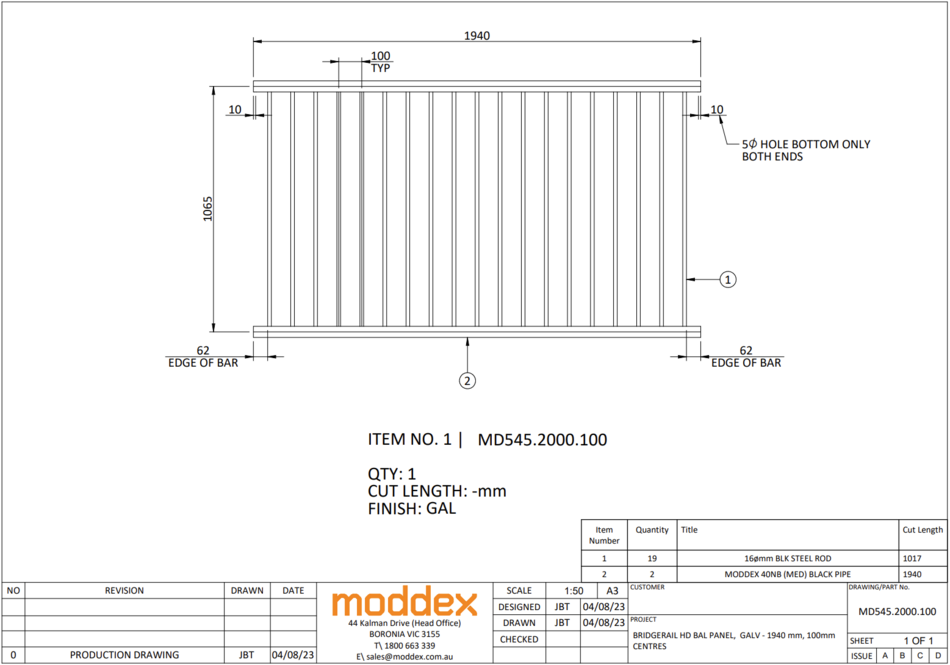

[[File:MD545.2000.100.PNG|frameless|950px]] | |||

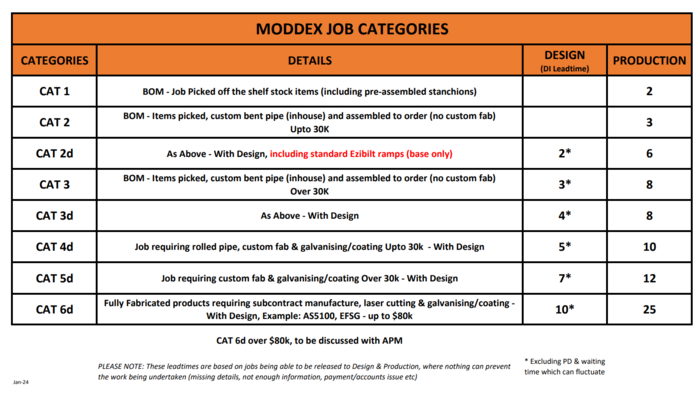

==30/01/2024 - Job Categories== | |||

<b>MEMO: Updated Job Categories</b> | |||

We have reviewed and updated the job categories with some additional information. | |||

Hopefully this provides some further clarity when assigning job categories. | |||

Changes below in red, updated version attached. | |||

Standard Ezibilt Ramps (you may need to check stock first) will be CAT 2D if it is just a ramp, if it requires handrail/balustrade, this will follow the normal Category levels. | |||

[[File:Moddex Job Catagories Jan 2024.png|frameless|700px]] | |||

=2023 Updates= | |||

All important updates sent in 2023 | |||

==30/11/2023 - Welded Stair Baseplates CB== | |||

<b>Welded Stair baseplates for CB</b> <b><span style="color:red">OUTDATED: We have MD251 & MD252 now to use</b></span style="color:red"> | |||

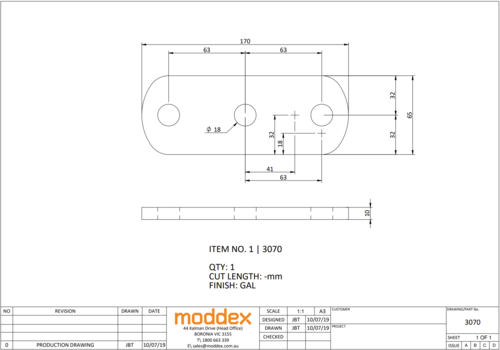

*When using any CB product on a stair, we either need to use a welded baseplate (as attached) or bend the pipe & use a MD232. When mounting to pre-drilled holes the 3070 needs to be used but any other time a bent post can be used. | |||

[[File:3070.PNG|frameless|500px]] | |||

==13/11/2023 - MDX Fixings Guide== | |||

<b>MDX Fixings Guide</b> | |||

*Please see the updated fixings guide. The only difference is the addition of the 50x50x3 square washer which needs to be used on every Bridgerail job. | |||

[https://moddex.sharepoint.com/:b:/s/General/EVNIjE9Mnz9OkDY3NB8ECBEB6B3hm054YGUTDFBlQ5KOiA?e=i6T4QX| MDX Fixings Guide] | |||

==24/10/2023 - Fitting Stock== | |||

<b>Update to fitting stocks & usage</b> | |||

Hi all, we have some updates for some fittings due to them being out of stock or heading that way. | |||

MD248.48 – start using MD148.48’s due to low stock | |||

MD271.48 – stop using for the moment. On CB30/AR45 use level end stanchions or closure panels to negate using these. We should have more at some point this year & I will advise when we get these. | |||

MD288.48 – keep designing these at the moment but there may come a time we need to revert to MD101.48/42 & MD748.42. | |||

MD230.48 – start designing MD130.48 as the MD230s are low in stock. | |||

==17/10/2023 - Bridgerail washer== | |||

<b>FX46003 - Square Washer, 50 x 50 x 3 - HDG</b> | |||

*We have made a code for the below washer which will be used on Bridgerail jobs to cover up the slot in the baseplate. This could be used on other custom baseplates that have slots to cover them as well. | |||

[[File:Bridgerail Washer.png|frameless|500px]] | |||

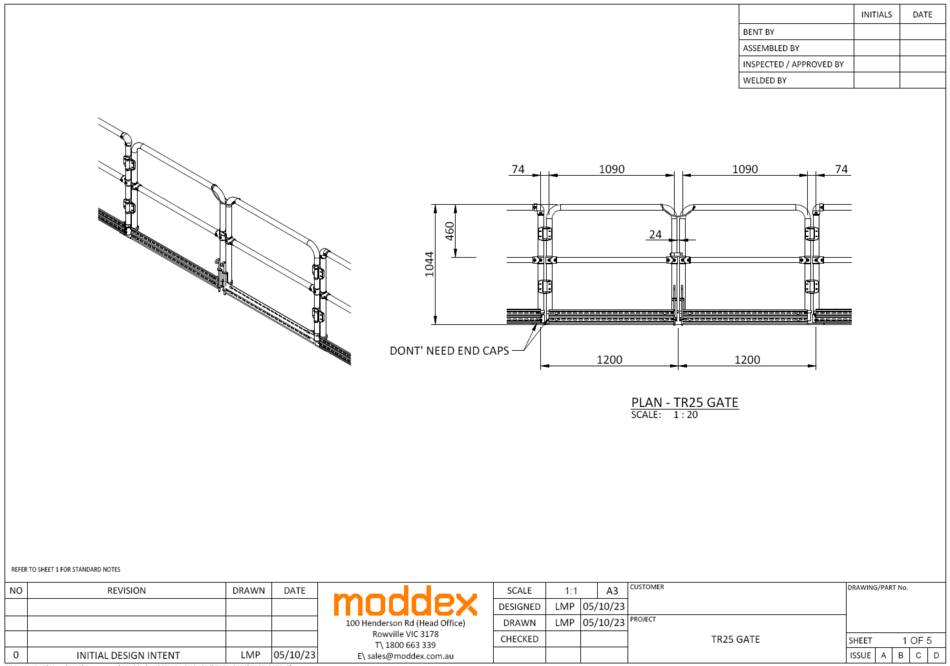

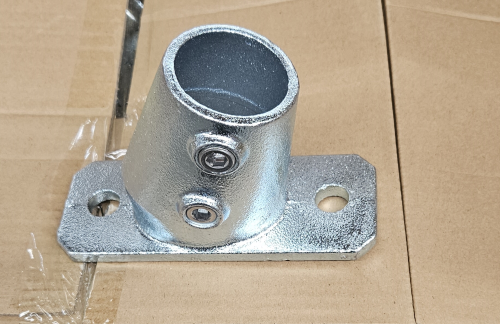

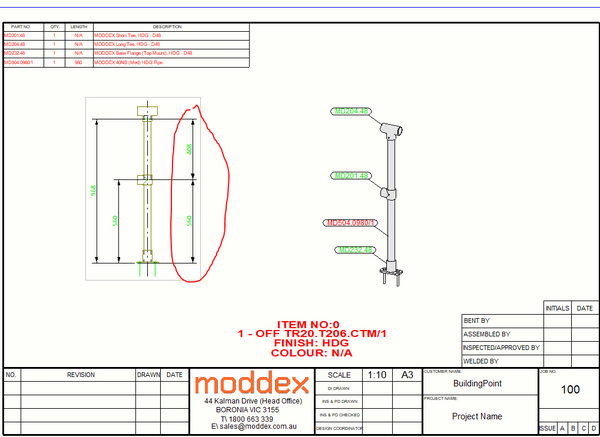

==06/10/2023 - A-Frame Gate== | |||

<b>A-Frame Gate</b> | |||

*Attached is how we are needing to design our A-Frame gates moving forward. The main thing I wanted to confirm what the position of the bow latch. Please position it in this location & detail a 10mm hole is required so production can drill it in the warehouse. | |||

[[File:A Frame Gate Layout.PNG|frameless|950px]] | |||

[[File:TR25Y - Mezzanine Floor Handrails & Gates.jpg|frameless|950px]] | |||

==28/08/2023 - MD252.48's unavailable== | |||

<b>MD252.48</b> | |||

*Similar to the MD251’s we only have stock of the style MD252’s. Please start using the attached model for any current & new jobs. They do have different hole centres so please keep an eye out for that. | |||

[[File:MD252 old.PNG|frameless|500px]] | |||

==03/08/2023 - Stanchion Dimensioning PDs== | |||

<b>Stanchion Dimensioning</b> | |||

Cruise has updated the templates to include these extra dimensions on stanchion. | |||

Please don’t remove them they were a request from production. | |||

The templates will be updated this afternoon so no stress if they don’t appear yet. Though as of tomorrow I will be looking for this on all pds. | |||

[[File:Stanchion Dimensions.png|frameless|600px]] | |||

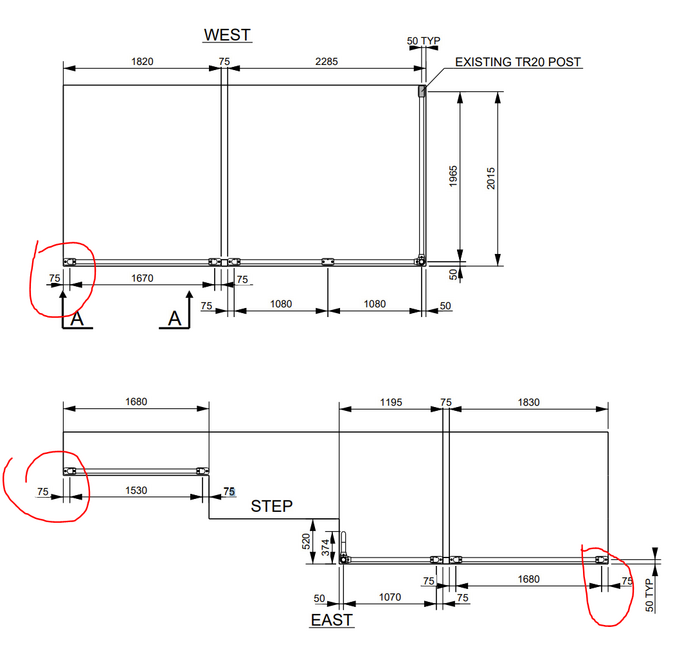

==21/07/2023 - Stanchion from building== | |||

<b>Edge distance to building should be 125mm from centre of stanchion to wall</b> | |||

Just had an installer call me about the edge distance on the below job. When we are mounting in from the edge of concrete or building, we need to stick to 125mm to the centre of the post. Currently at 75mm the edge distance is only 24mm from the fixing to the edge of concrete which is way too close. This has a chance of blowing out the concrete & drilling that close to the building is impossible. | |||

[[File:Edge distance to building.png|frameless|700px]] | |||

==21/07/2023 - Rolled Kickplate== | |||

<b>Rolled Flexalyte/Tuffgard</b> | |||

We have tested rolling flexalyte in QLD & VIC & have had good results come back with them. From now on if you have a job that is rolled we want to run with using flexalyte. I do want you to notify me when you have a job that has rolling to see if it will work as there are some examples where using 100x6 would be better. | |||

Attached is an example of how production require PDs to be detailed for these. It’s Tuffgard but follows the same principals. They have requested the side view be a little bigger to make it easier to view. | |||

[[File:Rolled Tuffgard.png|frameless|600px]] | |||

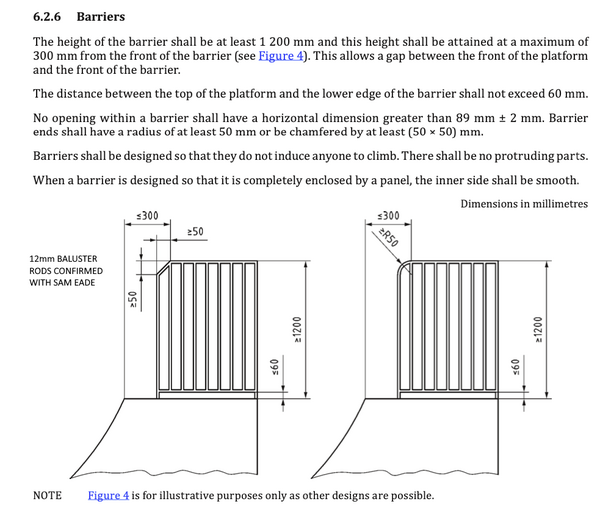

==19/06/2023 - Skatepark Standards== | |||

<b>Skatepark Standards</b> | |||

Just sending this as a reminder as some of you may have seen this already. If a job comes in that says it is a skatepark or looks like one, we need to follow the attached & below. | |||

*Height – 1200mm | |||

*Gaps – no bigger than 89mm in the panel. Underneath the panel can’t be bigger than 60mm so if it is top mount it has to use welded baseplates. | |||

*Ends – need to finish the closure panels to meet their requirements in the attached. They also need to finish before the start of a quarter pipe like the example. | |||

*Stanchion pipe – use heavy wall | |||

*Round bar – 12mm | |||

[[File:Skatepark Requirements.png|frameless|600px]] | |||

==05/06/2023 - 32Nb Standards== | |||

<b>32Nb Handrail - Change to standards</b> | |||

*MD150.42 - MODDEX Internal Connector - C42 (Pair) | |||

*MD725.42 - MODDEX Elbow (Internal) - C42 | |||

<b>Connecting email</b> | |||

There has been a change to the standards for early childhood centres & VIC schools. Attached is the new design we need to use with 32NB handrail for the moment. We are sourcing parts for our bender to be able to bend this in-house. | |||

Things to look out for. | |||

Pipe size – 32NB Medium = 42.4mm OD | |||

Pipe code | |||

* MD503 – Straight pipe | |||

* MD593 – Bent Pipe | |||

Stanchions – will remain 40NB as per normal | |||

Notes – there should be notes all over the CADHS stating when to use 32NB handrail. If not & you are unsure please ask me & I’ll check. | |||

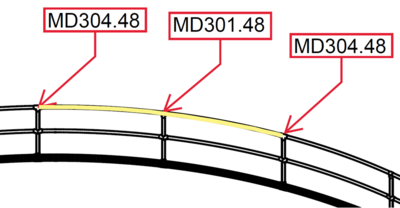

==02/06/2023 - Rolled Double Span== | |||

<b>Designing rolled jobs with double span pipes</b> | <b>Designing rolled jobs with double span pipes</b> | ||

*When designing rolled jobs we need to have 2 different types of posts to allow the pipe to go across 3 stanchions. There are issues with the casting of the MD304 which don’t allow pipe to go through it. Every 2nd post will need a MD301 mounted vertically which will allow the rail to go through. | *When designing rolled jobs we need to have 2 different types of posts to allow the pipe to go across 3 stanchions. There are issues with the casting of the MD304 which don’t allow pipe to go through it. Every 2nd post will need a MD301 mounted vertically which will allow the rail to go through. | ||

*On stairs, the MD305 will be machined out which will allow the pipe to be fed through with no issues. | *On stairs, the MD305 will be machined out which will allow the pipe to be fed through with no issues. | ||

[[File:Rolled MD301 example.PNG|frameless|400px]] | |||

==24/05/2023 - BS Closures== | |||

==24/05/2023== | |||

<b>Bikesafe Closure bends with handrail</b> | <b>Bikesafe Closure bends with handrail</b> | ||

*We’ve had some jobs recently that have been picked up with not having 50mm clearance between the closure of the handrail & bikesafe rail. | *We’ve had some jobs recently that have been picked up with not having 50mm clearance between the closure of the handrail & bikesafe rail. | ||

| Line 18: | Line 359: | ||

[[File:Correct Bikesafe design.jpg|frameless|400px]] | [[File:Correct Bikesafe design.jpg|frameless|400px]] | ||

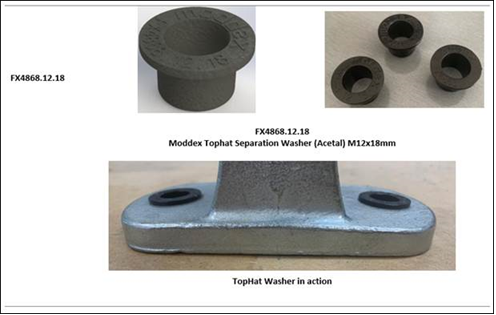

==24/05/2023 - M12 Washers== | |||

<b>Replacement Isolation Top Hat Washer for M12 Fixings</b> | |||

==24/05/2023== | |||

*The 3115 top hat washer is being phased out & in it’s place will be the FX4868.12.18. | *The 3115 top hat washer is being phased out & in it’s place will be the FX4868.12.18. | ||

*This new top hat isolation washer can be used in any of our standard 2 or 4 hole baseplates & can only be used alongside M12 fixings. These will NOT work with M16 fixings. | *This new top hat isolation washer can be used in any of our standard 2 or 4 hole baseplates & can only be used alongside M12 fixings. These will NOT work with M16 fixings. | ||

| Line 26: | Line 366: | ||

[[File:Top hat washer for M12.PNG|frameless|500px]] | [[File:Top hat washer for M12.PNG|frameless|500px]] | ||

==04/05/2023== | ==04/05/2023 - 3300's== | ||

<b>Swapped from using UFJ90-40B to 3300</b> | <b>Swapped from using UFJ90-40B to 3300</b> | ||

==28/03/2023== | ==28/03/2023 - MD322.48 and MD326.48 usages== | ||

<b>MD322.48 and MD326.48 usages</b> | <b>MD322.48 and MD326.48 usages</b> | ||

*MD322.48 & MD326.48 CANNOT be used in any balustrade panels or in the entire Tuffrail system, due to the loads these systems are tested & certified to. You are still able to use them in the handrails of our Assistrail, Bikesafe (rails only), Bridgerail (handrail only) & Conectabal (handrail only) systems, but bent pipes are your first option. | *MD322.48 & MD326.48 CANNOT be used in any balustrade panels or in the entire Tuffrail system, due to the loads these systems are tested & certified to. You are still able to use them in the handrails of our Assistrail, Bikesafe (rails only), Bridgerail (handrail only) & Conectabal (handrail only) systems, but bent pipes are your first option. | ||

| Line 35: | Line 375: | ||

[https://moddex.sharepoint.com/:x:/s/General/Ec6jQT7LdsxPlLeaTYJqAFcB3GOS7MguodmNexa6ClG-Aw?e=gJ7dtA| MD322.48 & MD326.48 Usages] | [https://moddex.sharepoint.com/:x:/s/General/Ec6jQT7LdsxPlLeaTYJqAFcB3GOS7MguodmNexa6ClG-Aw?e=gJ7dtA| MD322.48 & MD326.48 Usages] | ||

==15/03/2023== | ==15/03/2023 - M12Chemset/Domenuts School Projects== | ||

<b>M12 Chemsets and M12 Domenuts required on all school projects</b> | <b>M12 Chemsets and M12 Domenuts required on all school projects</b> | ||

*Just a friendly reminder that ALL school projects (primary school, high school, kindergarten, childcare etc) require M12 Dome Nuts (FX43113.12) included alongside M12 Chemset fixings (FX13113.12.160 or FX13113.16.190) if you are fixing to concrete. | *Just a friendly reminder that ALL school projects (primary school, high school, kindergarten, childcare etc) require M12 Dome Nuts (FX43113.12) included alongside M12 Chemset fixings (FX13113.12.160 or FX13113.16.190) if you are fixing to concrete. | ||

Latest revision as of 22:52, 23 October 2025

This page includes direct information and updates about products, fittings, fixings, design updates, and any other relevant information that the Design Academy drafters will need to use. This information will usually be copied directly from emails received from Ryan or Iain.

2025 Updates

24/10/2025 - Updates to Kliptread Fixings

Kliptread fixing codes have been updated to the following (Black: old code, Green: new code)

2/10/2025 - MD580 Panels cannot be tweaked

Any panels to suit 1500mm high balustrade cannot be tweaked & have to be fabbed. The benches for tweaking aren’t big enough but the main issue is the 16mm bars make it harder to do so. Please keep this in as anything angled will be required to be on the FAB PDs & the parts in the pick/pack to make the panels.

30/09/2025 - MD768L - Custom bracket for CB20 Top Mount

We now have a code for the longer MD768 bracket when Tuffgard is used on CB20 Top Mount. For other mounts we can still use the MD298.48 mounted upside down as there is clearance between the baseplate & bottom of the panel.

26/09/2025 - 3300 welds on panels

Part of our welding procedure when using 3300 elbows requires a 3mm gap between the fitting & the pipe. Moving forward can you please include this in your models which will allow production to follow the correct procedure & not having to trim pipes down. For those using Tekla this should be automated already in the plug-ins but for those not you will need to allow for this.

01/09/2025 - New Core Depth in WA

In WA our standard core depth is now 350mm into the ground. In WA when we core mount its normally into limestone blocks which are 350x350mm, so this depth puts us as far into the block as we can go.

21/08/2025 - New Bend To Add Green To

On the bend below, we need green at the end. The type of bend needs to be done different than normal so the green is required at the end of the bend. It’s only required where there is a small bend at the end of it.

8/08/2025 - New MD201.48 Design

A new update to the design of the MD201.48 has been released. The shape is different to allow it to go around 90° bends. There is a design issue though with the stop in the fitting for pipe/panels coming in. This means standard panels will need to be cut down & that we can't use MD504.1940 pipe on end stanchions where this is used. The design will be fixed in REV4 & we will advise once that has been released.

23/07/2025 - New weld-in elbow - 3300.REV03

Moving Forward, the new weld-in elbow for panels & handrails needs to be 3300.REV03. This supersedes the UFJ90-40B

22/07/2025 - New Dimension Standard for Install Drawings

Moving Forward, install drawings will need to show both the relative and absolute dimensions for stanchion positions. This will show both the rolling dimension from 0, as well as the centre-to-centre dimensions.

In the properties pane, choose the +Moddex_Install option from the presets, or alternatively, select Relative and Absolute from Straight dimension field. Ensure that your firm folder has been updated using Trimble Connect Sync.

24/06/2025 - New Pick/Pack

We’ve made a few improvements to the pick/pack list to make life a little easier for production.

1. The pick & pack list now has colours in some of the columns. This is used just to remind production that they need to be filled out.

2. There is a new tab called Rods Report. This needs to be used when we have custom fab panels as production will cut the rods without needing to look over the drawings.

a. Rather than compiling all lengths of round bar into full lengths, with a quantity, they want it broken down into cut lengths & quantities.

b. With the angle, only note that if there is an angle, both top & bottom. If there is an angle on 1 side of the rod, don’t note it & it can be trimmed to suit before it is welded in.

c. All angled bars, measured from long to short (so along 1 side of the bar).

d. If only one end is angled, measure to the longest end.

3. We will still need to include the total QTY of round bar in the pick list, as we still do now, as this is used to take stock out of the system.

4. Please include the item number on the rod report.

23/06/2025 - New Stanchion Runnings Dimensions

The below photo is a snip of a stanchion from Tekla. Production has requested that we include the running dimensions on the right of the snip on all our drawings from this point forward.

11/06/2025 - Top Hat Washer Differences

Below is a photo showing the codes, descriptions & where each washer gets used.

22/01/2025 - Ezibilt - detailing Ramp Tips

The notes need to be as per the below when the job is supply only. If you have any questions please reach out. Moving forward we need to add extra detail to our Dis & Install drawings for Ezibilt regarding the concrete ramp tip. Please keep the attached drawing as an example but essentially the customer pours that slab for us to mount on & the ramp tip is poured by our installers. We need to always have the below few points on the drawing.

Posts on the ramp tip to be inground 250mm Ramp tip to be 150mm thick at it’s lowest side Ramp tip & concrete to be shaded but different colours to make it obvious Notes on the drawing stating who is pouring what Moddex to pour ramp tip Customer to pour concrete for footings Dimensions from a datum showing where the tip is located

If you have any questions or what your drawings checked while doing them please reach out.

Further to this, the notes about Customer & Moddex pouring sections of concrete only apply if we are installing. You should be able to tell on the CADHS if we are installing but if you are unsure please ask myself or another DC.

The notes need to be as per the below when the job is supply only.

2024 Updates

All important updates sent in 2024

11/12/2024 - Embedment depth on DI's & Installs

We need to start showing our embedment depth on Design Intent & Install drawings. Below are some examples of what we need to show and the correct embedment's for different fixing types. When mounting to steel please detail the thickness of the steel we are mounting into & the length of the bolt.

02/10/2024 - Designing Powder Coated Aluminium jobs

Moving forward with powder coated Aluminium Tuffrail jobs, please design your rails as single span. There have been issues reported with the pipes not running through fittings or scratching. Example images below.

24/09/2024 - Flexalyte and Tuffgard - Radius achievable without rolling

We've done some testing to see how much our Flexalyte & Tuffgard can be pulled around a curve to avoid rolling. Flexalyte has increased to a radius of 10000mm. While for Tuffgard it is now currently sitting at 3000mm without rolling.

10/06/2024 - Change to UFJ90-40B from 3300

We have to change from our 3300 weld-in elbows to a new design for the UFJ90-40B. Please start drawing this in now as stocks of 3300 are getting low.

10/06/2024 - Weld Symbols on Drawings

Good Morning team, to improve our processes & help out production, we now need to start including weld symbols to our fabrication drawings.

Weld symbols are a representation of the type, size, finish & process of a weld, all bundled up into an easy to read, nationally recognized symbol. This was not something we used to do previously, however it will be a huge improvement to our drawings. This will also be an improvement for any out-of-house company that we provide drawings for welding, as they will now have a clear understanding of the welds we require. It also covers our butts, in the case that something is not welded to the spec we specify.

Below is a link to the Moddex Wiki, with a dedicated page to weld symbols. The page contains details on understanding what a weld symbol is, example production drawings containing different types & sizes of welds & their associated symbols with explanations & also some instructions on how to create weld symbols within Tekla (make sure to click on the [Open] text on each sub heading, this will show the drawings). Over the next couple of weeks I’ll also try & add in instructions for Solidedge & Solidworks as well.

http://20.211.196.52:8080/index.php/Weld_Symbols

I’ll have a this added to the Master CAD Checklist also. If you have any questions or want some training I am free to help.

04/06/2024 - Adding more details into Project name titleblock

Hi all,

A recommendation from sales was to add more details in our title blocks regarding the project name of a job. Below are 2 examples of what they are after. This is mainly for the bigger jobs with multiple sections to make it easier to know what you are looking at. If you are unsure of what to name your drawing, it is something noted on the customer's drawings or markups.

(ADD PICTURES LATER)

03/06/2024 - MD251 & MD252

We now have stock of MD251 & MD252 It’s been found out that we have been using an old model of our stair baseplates for 2 or so years Models can be found at: \\design-academy\Reference Parts

16/05/2024 - New pick/pack template

Hi all,

We have added 2 extra tabs to the pick/pack list. Please put them in order as per the attached. The Auto Saw Cut List is to be left blank & is to be filled out by production if/when required. This is just to be copied from this template into the pick/pack you create.

The customer delivery note is to be a copy of the pack list but this is for the customers to fill in when receiving the product on-site. For those using Tekla there is a new report template for this as per what I’ve circled below. @Hansel let me know if your team doesn’t have this. For those in SolidEdge/Works you’ll need to copy what’s in the pack list to the customer delivery note tab.

12/04/2024 - Detailing for Mesh Panels

Hi all,

When it comes to detailing mesh panels on PDs please follow the attached to avoid any issues when it is fabricated.

Also, the mesh needs to face inwards towards the path, ramp & stair & the rods are behind that.

If you have any questions please reach out. Regards,

12/04/2024 - Optimising Stanchion Spacings

Hi all,

You’ll see below on new CADHS’s that new text that I’ve circled below. What this means is even if the job has been quoted as 1 or 1.5m spacings we can extend up to 2m with no issues. Sales sometimes reduce the spacings when quoting to bump up the price but we aren’t getting those wins if we follow that.

It will either be Yes or No. If you have a job where it isn’t put in, please reach out & we’ll confirm what to do.

Hopefully this makes sense but if you have any questions please reach out.

11/04/2024 - Details on Curved Kickplate

Hi all,

A request from production is to add in another leader not on the section view detailing the front, as I’ve sketched up. This will eliminate any confusion our rollers have in deciding which is the front/back.

Please also make the section view (in this case AZ-AZ) larger so it’s easy to see the profile when it’s printed on an A4 sheet.

11/04/2024 - 3rd Angle Projection

Hi all,

We need to start detailing our fabricated panel in 3rd angle projection as per the attached. Only need to do these on 90°, 180° or funky design and isn’t required on a flat angled panel.

Please also include the 2 below dimensions on 90° or 180° panels as this helps production they have made it correctly as it gives them something to double-check.

If you have any questions please reach out.

09/04/2024 - RE: MD251.48

Hi all,

We now have stock of our design for the MD251.48 so please use that rather than the old model. If you have any questions please reach out.

09/02/2024 - 1200mm High Panels

1200mm high panels

Just sending an email for these 2 panels to note where & when they are used.

MD535 – 12mm bar (1050mm cnetres)

- Gets used on normal CB products when they are required at 1200mm high

MD545 – 16mm bar (1065mm centres)

- Gets used on bridgerail jobs

30/01/2024 - Job Categories

MEMO: Updated Job Categories

We have reviewed and updated the job categories with some additional information. Hopefully this provides some further clarity when assigning job categories. Changes below in red, updated version attached.

Standard Ezibilt Ramps (you may need to check stock first) will be CAT 2D if it is just a ramp, if it requires handrail/balustrade, this will follow the normal Category levels.

2023 Updates

All important updates sent in 2023

30/11/2023 - Welded Stair Baseplates CB

Welded Stair baseplates for CB OUTDATED: We have MD251 & MD252 now to use

- When using any CB product on a stair, we either need to use a welded baseplate (as attached) or bend the pipe & use a MD232. When mounting to pre-drilled holes the 3070 needs to be used but any other time a bent post can be used.

13/11/2023 - MDX Fixings Guide

MDX Fixings Guide

- Please see the updated fixings guide. The only difference is the addition of the 50x50x3 square washer which needs to be used on every Bridgerail job.

24/10/2023 - Fitting Stock

Update to fitting stocks & usage

Hi all, we have some updates for some fittings due to them being out of stock or heading that way.

MD248.48 – start using MD148.48’s due to low stock

MD271.48 – stop using for the moment. On CB30/AR45 use level end stanchions or closure panels to negate using these. We should have more at some point this year & I will advise when we get these.

MD288.48 – keep designing these at the moment but there may come a time we need to revert to MD101.48/42 & MD748.42.

MD230.48 – start designing MD130.48 as the MD230s are low in stock.

17/10/2023 - Bridgerail washer

FX46003 - Square Washer, 50 x 50 x 3 - HDG

- We have made a code for the below washer which will be used on Bridgerail jobs to cover up the slot in the baseplate. This could be used on other custom baseplates that have slots to cover them as well.

06/10/2023 - A-Frame Gate

A-Frame Gate

- Attached is how we are needing to design our A-Frame gates moving forward. The main thing I wanted to confirm what the position of the bow latch. Please position it in this location & detail a 10mm hole is required so production can drill it in the warehouse.

MD252.48

- Similar to the MD251’s we only have stock of the style MD252’s. Please start using the attached model for any current & new jobs. They do have different hole centres so please keep an eye out for that.

03/08/2023 - Stanchion Dimensioning PDs

Stanchion Dimensioning

Cruise has updated the templates to include these extra dimensions on stanchion. Please don’t remove them they were a request from production. The templates will be updated this afternoon so no stress if they don’t appear yet. Though as of tomorrow I will be looking for this on all pds.

21/07/2023 - Stanchion from building

Edge distance to building should be 125mm from centre of stanchion to wall

Just had an installer call me about the edge distance on the below job. When we are mounting in from the edge of concrete or building, we need to stick to 125mm to the centre of the post. Currently at 75mm the edge distance is only 24mm from the fixing to the edge of concrete which is way too close. This has a chance of blowing out the concrete & drilling that close to the building is impossible.

21/07/2023 - Rolled Kickplate

Rolled Flexalyte/Tuffgard

We have tested rolling flexalyte in QLD & VIC & have had good results come back with them. From now on if you have a job that is rolled we want to run with using flexalyte. I do want you to notify me when you have a job that has rolling to see if it will work as there are some examples where using 100x6 would be better.

Attached is an example of how production require PDs to be detailed for these. It’s Tuffgard but follows the same principals. They have requested the side view be a little bigger to make it easier to view.

19/06/2023 - Skatepark Standards

Skatepark Standards

Just sending this as a reminder as some of you may have seen this already. If a job comes in that says it is a skatepark or looks like one, we need to follow the attached & below.

- Height – 1200mm

- Gaps – no bigger than 89mm in the panel. Underneath the panel can’t be bigger than 60mm so if it is top mount it has to use welded baseplates.

- Ends – need to finish the closure panels to meet their requirements in the attached. They also need to finish before the start of a quarter pipe like the example.

- Stanchion pipe – use heavy wall

- Round bar – 12mm

05/06/2023 - 32Nb Standards

32Nb Handrail - Change to standards

- MD150.42 - MODDEX Internal Connector - C42 (Pair)

- MD725.42 - MODDEX Elbow (Internal) - C42

Connecting email

There has been a change to the standards for early childhood centres & VIC schools. Attached is the new design we need to use with 32NB handrail for the moment. We are sourcing parts for our bender to be able to bend this in-house.

Things to look out for.

Pipe size – 32NB Medium = 42.4mm OD

Pipe code

- MD503 – Straight pipe

- MD593 – Bent Pipe

Stanchions – will remain 40NB as per normal

Notes – there should be notes all over the CADHS stating when to use 32NB handrail. If not & you are unsure please ask me & I’ll check.

02/06/2023 - Rolled Double Span

Designing rolled jobs with double span pipes

- When designing rolled jobs we need to have 2 different types of posts to allow the pipe to go across 3 stanchions. There are issues with the casting of the MD304 which don’t allow pipe to go through it. Every 2nd post will need a MD301 mounted vertically which will allow the rail to go through.

- On stairs, the MD305 will be machined out which will allow the pipe to be fed through with no issues.

24/05/2023 - BS Closures

Bikesafe Closure bends with handrail

- We’ve had some jobs recently that have been picked up with not having 50mm clearance between the closure of the handrail & bikesafe rail.

- When doing bikesafe with handrail, we need to design the closure bends of the bikesafe as per the last attached photo.

Incorrect

Correct

24/05/2023 - M12 Washers

Replacement Isolation Top Hat Washer for M12 Fixings

- The 3115 top hat washer is being phased out & in it’s place will be the FX4868.12.18.

- This new top hat isolation washer can be used in any of our standard 2 or 4 hole baseplates & can only be used alongside M12 fixings. These will NOT work with M16 fixings.

- As below is a small image of the washers & what they look like installed in a MD245.48 baseplate

04/05/2023 - 3300's

Swapped from using UFJ90-40B to 3300

28/03/2023 - MD322.48 and MD326.48 usages

MD322.48 and MD326.48 usages

- MD322.48 & MD326.48 CANNOT be used in any balustrade panels or in the entire Tuffrail system, due to the loads these systems are tested & certified to. You are still able to use them in the handrails of our Assistrail, Bikesafe (rails only), Bridgerail (handrail only) & Conectabal (handrail only) systems, but bent pipes are your first option.

- Balustrade systems will need to either be fully welded panels or use corner/adjustable stanchions. Tuffrail will always need to use bent pipe or corner/adjustable stanchions.

M12 Chemsets and M12 Domenuts required on all school projects

- Just a friendly reminder that ALL school projects (primary school, high school, kindergarten, childcare etc) require M12 Dome Nuts (FX43113.12) included alongside M12 Chemset fixings (FX13113.12.160 or FX13113.16.190) if you are fixing to concrete.